The marine world calls for top-notch accuracy and toughness in every piece. Think hull frames or deck setups. One key tool that delivers this skill is CNC plasma cutting. This smart method has changed how shipyards and boat builders make special aluminum items.

In ship construction, big parts need to join up just right. They face rough seas. Accuracy isn’t extra—it’s a must. CNC plasma cutting shapes thick aluminum sheets with sharp precision. It cuts down waste. Plus, it boosts the build’s strength.

Fundamentals of CNC Plasma Cutting Technology

CNC plasma cutting holds a big spot in today’s making processes.

What is CNC Plasma Cutting?

CNC stands for Computer Numerical Control. Plasma cutting uses a fast stream of charged gas—plasma—to slice through metals that conduct electricity, like aluminum. Computers guide it all via CAD files. That means tricky shapes. And exact repeats every time.

How Plasma Arcs Cut Through Thick Aluminum Sheets

It starts with an electric spark. This jumps from an electrode to the aluminum sheet. The spark turns gas into plasma. Temperatures hit over 20,000°C. That’s super hot. It melts the metal quick. Then, the gas blast pushes the liquid bits away. Clean slices appear. Even on thick plates.

Advantages Over Traditional Cutting Methods

CNC plasma beats old ways like saws or oxy-fuel torches. Here’s why. It cuts way faster. Heat stays low, so the material doesn’t twist much. You can handle wild shapes easily. And cleanup after is small. These perks fit perfect for custom aluminum bits in salty sea spots.

Challenges of Profiling Thick Aluminum Sheets

Sure, the upsides shine. But shaping thick aluminum for boats brings tough hurdles. Experts use smart tricks and know-how to fix them.

Heat Distribution and Material Warping

Aluminum spreads heat fast. That’s great sometimes. But in plasma cutting, it causes uneven warmth. Big sheets can bend or twist. Not good. So, tight controls step in. Pre-heating helps too. These steps keep things flat.

Maintaining Dimensional Accuracy in Large-Scale Components

Boat parts like walls or braces stretch meters long. A tiny slip-up ruins the lineup. CNC setups lock in CAD plans. Every slice matches. That holds the size steady from start to end.

Surface Finish Considerations for Marine Applications

Sea gear needs slick tops. Why? To fight rust and seal tight. Plasma edges look good mostly. Still, extra polish might come next. It’s key for salt spray hits.

Custom Plasma Cutting for Marine and Shipyard Components

Boats call for one-of-a-kind fixes more than ever. Custom plasma cutting fills that gap big time.

Meeting the Demands of Custom Aluminum Parts in Shipbuilding

Ships differ by job—hauling goods, fighting foes, or fun cruises. Custom CNC plasma shapes each bit to fit. Take hulls and walls. They use thick sheets. Cuts stay super tight. Strength holds vs. wave pounds.

Decks take heavy weights. Yet they stay light. Custom profiles mix both well.

Then there are special hooks and mounts. They link radars, ropes, or rescue boats smooth. No hit to speed or safe spots.

Benefits of Customization in Harsh Marine Environments

Tailor-made boosts more than fit. It adds years. Smart designs cut weak points. Loads spread even. That’s huge in salt baths and sun blasts. Vessels last longer.

CNC Precision Machining After Plasma Cutting

Plasma sets the outline. But extra steps often tweak it finer.

Post-Cut Processing for Enhanced Accuracy

After the slice, refine happens. Milling adds smooth flats. Drilling pokes holes. Tapping threads them. All for joining or fixing in place. It matches other boat gear just right.

What’s more, surfaces get coats. Anodizing or powder shields from rust.

Integration with Other Fabrication Processes

These machined bits slide into welds, rivets, or screws easy. It speeds up yard work. Flow stays smooth.

Material Selection: Why Aluminum is Preferred in Marine Industries

Aluminum tops the list for sea jobs. Its traits match water work spot on.

Properties of 6061 and 6063 Aluminum Alloys

Folks pick from series like 3030, 4040, 4545, 5050, 6060, 6061, and 6063.

Corrosion Resistance in Saltwater Environments

6061 and 6063 fight salt rust well. They hold up over time at sea. That’s vital for staying strong.

Strength-to-Weight Ratio Benefits for Vessels

High pull strength comes light. Fuel saves big. Strength doesn’t dip. Boats run better.

Choosing the Right Alloy for Specific Shipyard Applications

Go 6061 for heavy lifts. It’s tougher. Pick 6063 for sleek looks or fancy cuts. Think rails or trim bits.

Introducing XiHui Aluminium as a Trusted Partner in Aluminum Fabrication

Marine makers hunt solid teams for custom aluminum work. XiHui Aluminium steps up. They bring years of solid know-how.

Overview of XiHui Aluminium’s Capabilities

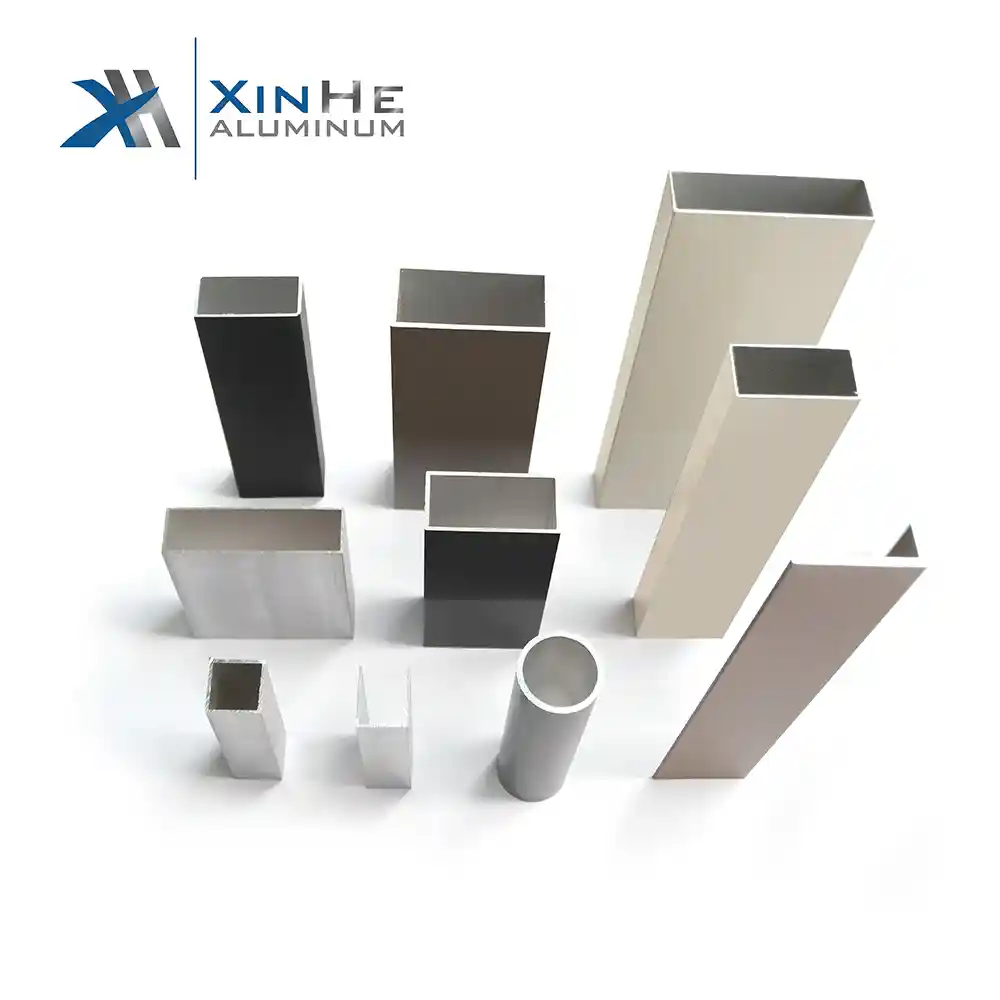

XiHui Aluminium roots in making industrial aluminum profiles. These start as alloy melts. Heat them. Push through dies. Shapes pop out—various sections.

Expertise in Extruded Aluminum Profiles

They shine in extrusion lines. Think 6060, 8080, 9090, and 100100 series. These build stiff bases. Custom tweaks fit marine needs.

OEM CNC Machining Services for Custom Metal Parts

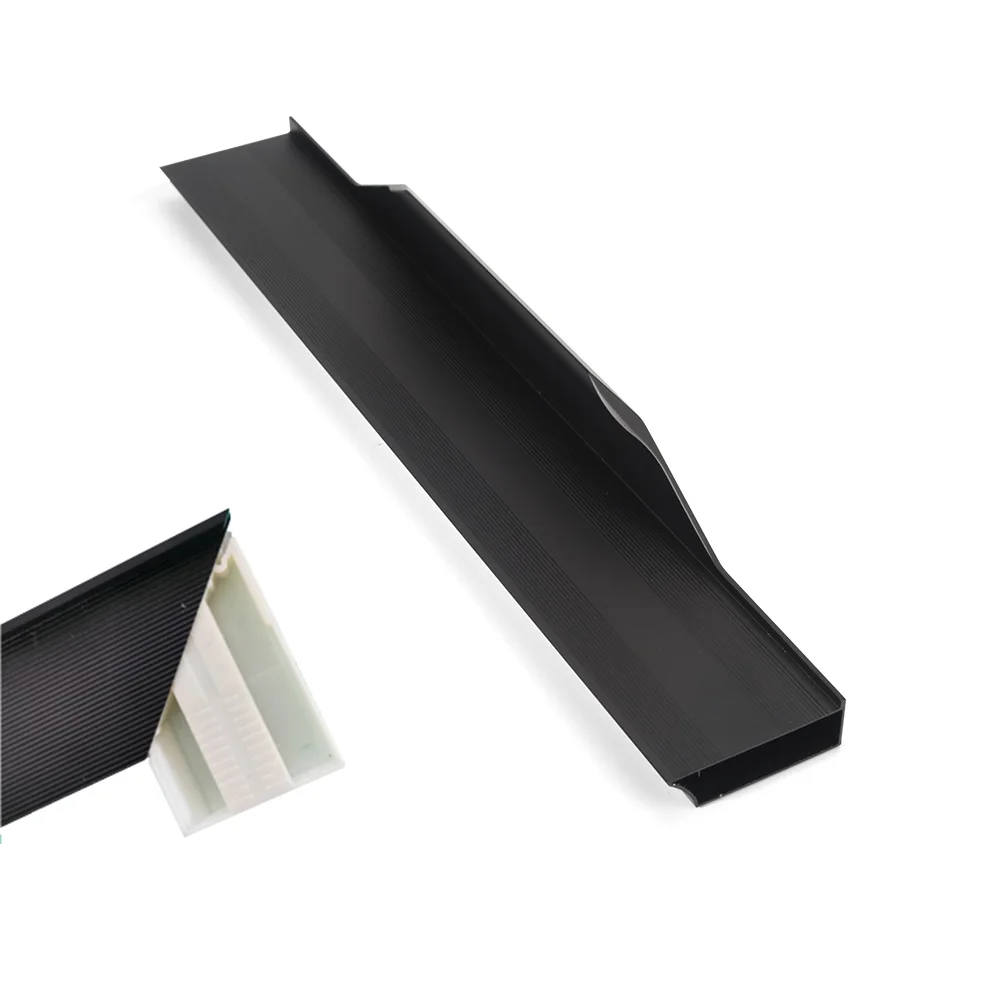

OEM work covers size shifts and color picks. Plus, drills and taps after. One shop from push to pack.

Commitment to Quality and Global Supply Chain Support

33 years in making and selling. Tens of thousands of molds ready. Wide styles. Custom ones too. World shipping hits on time. Stock or CAD specials. No low buy rules on basics like anodized silver-white or black coats.

FAQs:

Q1: What makes CNC plasma cutting suitable for marine-grade aluminum?

A: It keeps tight fits on thick sheets. That builds strength in wild sea spots. Fast runs and low heat bends make it prime for tough custom aluminum ship bits.

Q2: Can XiHui Aluminium handle small-batch orders?

A: Sure. No low buy on stock like anodized silver-white profiles. That opens doors for test runs before big makes.

Q3: How does post-machining improve corrosion resistance?

A: Post CNC plasma slices, parts get anodizing. It builds a shield layer. That fights salt wear in sea air.