In the fast-changing world of automation, robotic arms are leading the way in factory and tech progress. Their success, however, depends greatly on how strong and exact their parts are. This is where precision CNC machining comes in, playing a key part. It’s a crucial process. First of all, it makes it possible to create very precise, tough, and detailed parts. Thus, CNC machining has become the foundation for making robotic arms in all sorts of industries.

The Role of CNC Machining in Robotic Arm Development

Precision CNC machining is vital in robotics. This is because of its unique power to meet very strict measurements and do so again and again.

Enhancing Precision and Repeatability in Automation

Robotic arms work in tough environments. These settings demand steady movement patterns and spot-on positioning. CNC machining makes sure every single part is made within very tight limits, which helps with dependable motion control. What’s more, the consistency that precision CNC machining offers cuts down on working mistakes in automated systems. This improves both output and safety.

Supporting Complex Geometries and Functional Requirements

Today’s robotic arms often have complex shapes. For instance, they might have internal paths for wires or fluids, curved surfaces for their joints, and lightweight frames to move faster. CNC machines—especially the multi-axis types—can create these detailed shapes with great accuracy. This is something older ways of making things can’t easily do.

Meeting Tight Tolerances for High-Performance Applications

Some jobs, like putting together airplanes or helping in surgery, need amazing accuracy. Precision CNC machining can create parts with tolerances as small as ±0.01mm. So, it’s perfect for making pieces that have to fit together perfectly and handle moving forces.

Key Structural Components of Robotic Arms Produced by CNC Machining

CNC machining helps create almost every working part of a robotic arm, from its main frame to its specialized end tools.

Joints and Rotational Mechanisms

Joints are the center of a robotic arm’s ability to move. They need parts that can turn smoothly with a load and stay in line.

- Bearing Housings and Shaft Interfaces: Bearing housings need to be machined with perfect roundness for smooth turning. In the same way, shaft connections need to be aligned just right to prevent any wobble when moving.

- Gear Assemblies for Motion Control: Gears used in servo-powered joints are often custom-made. This is to lessen any looseness and make the transfer of torque more effective. These parts really benefit from the exactness of CNC machines.

Arm Segments and Linkages

The pieces between the joints need to be strong but not heavy. This is so they can hold things without causing problems from too much weight when moving.

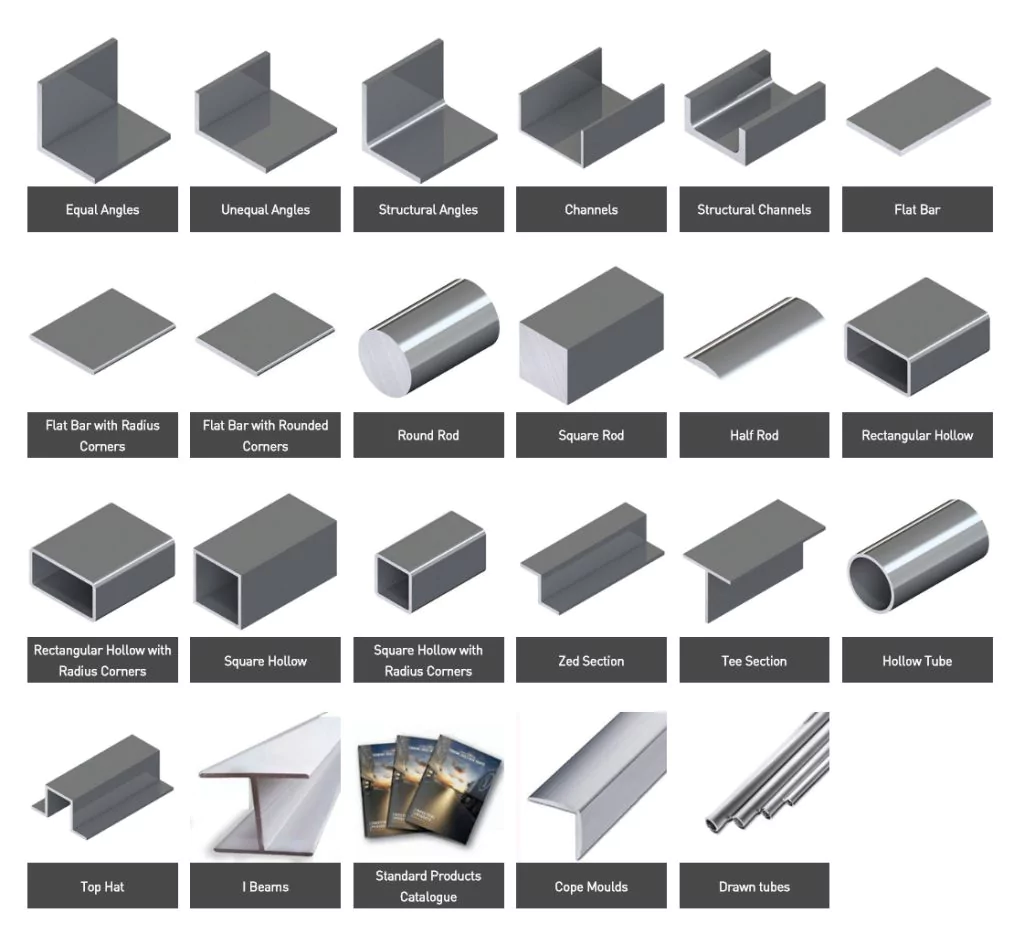

- Load-Bearing Profiles with Optimized Weight Distribution: These parts are designed to have a great strength-to-weight ratio. This is very important in active robotic uses to lower inertia and make them react faster.

- Custom-Machined Aluminum Structures: These aluminum structures are available in stock colors like anodized silver and black. They are made to resist rust and look good through finishes like anodizing. This makes them great for high-tech places.

End Effectors and Tooling Interfaces

End effectors are the parts that do the work—like gripping, welding, or cutting. They have to be made perfectly for each different job.

- Grippers, Welders, and Cutters Tailored to Task Requirements: CNC machining lets creators make unique shapes that fit certain tool needs. Besides, they can do this while keeping the part strong enough to handle stress.

- Material Considerations for Durability and Accuracy: High-quality end effectors often use tough materials like hardened steel or titanium alloys. These are shaped by precision CNC machining to make sure they don’t wear out after being used for a long time.

Sensor Mounts and Electronic Enclosures

Sensors give feedback that is very important for a robot to work correctly. Their mounts have to keep the fragile electronics safe and put them in the best spot.

- Protective Housing for Feedback Systems: Machined cases protect sensors from things like dust, shaking, or chemicals. They still have openings for adjustments or repairs.

- Integration of Wiring Channels and Connectors: Many machined parts have built-in paths or ports that make wiring easier. This is a very important point in small robotic setups.

Material Selection for CNC-Machined Robotic Components

The choice of material has a direct impact on how a part works. This includes things like its weight, strength, ability to handle heat, and how easy it is to work with.

Aluminum Alloys for Lightweight Strength

Aluminum is still a favorite material. It has a great mix of strength and low weight, which is just what robotics needs.

- Common Grades: 6061, 6063, 7075: Besides the usual high-strength alloys like 6061 and 7075, a variety of industrial profiles (like the 3030, 4040, and 6060 series) are also used. These types have different levels of hardness (9-16HW) that are good for various structural needs in robotic arms.

- Surface Treatments: Anodizing, Powder Coating: The anodizing process adds a surface that resists rust and wear. This makes aluminum parts perfect for tough factory settings where they might get wet or be around chemicals.

High-Strength Metals for Load-Bearing Parts

Stainless steel offers better tensile strength. On the other hand, titanium gives a high strength-to-weight ratio. Both are often used where the physical stress is greatest, such as in the base joints or in lifters for heavy items.

Engineering Plastics for Insulation and Flexibility

Plastics like PEEK (Polyether ether ketone), Delrin (acetal), and Nylon are used for parts that don’t carry weight. They are chosen when electrical insulation or less friction is needed during movement.

Advantages of Using CNC Machining in Robotic Arm Manufacturing

There are many good reasons to use precision CNC machining to produce robotic arms:

- Dimensional Accuracy and Consistency: CNC machines ensure that every single unit is made exactly to the plan. This is a must for modular robot systems where parts need to be interchangeable.

- Scalability from Prototyping to Mass Production: CNC methods can go from making just one prototype to large-scale production easily. They do this without losing quality or needing new tool setups. This is great for the step-by-step product design common in robotics research.

- Reduced Lead Times through Advanced Automation: Automated toolpaths cut down on human mistakes and make the manufacturing process much faster than doing it by hand. As a result, this gets products to the market much quicker.

- Customization for Application-Specific Needs: It doesn’t matter if it’s a medical robot that needs body-safe materials or a warehouse robot that needs a tough case. CNC machining can handle endless custom options in an efficient way.

Criteria for Selecting a CNC Machining Partner for Robotics Projects

Picking the right partner is key. It not only leads to a successful manufacturing run but also ensures your automation system will be dependable for years to come.

- Industry Experience in Automation Component Fabrication: A supplier who knows about the standards for automation will understand the small details. For example, they’ll know about needs for vibration control or sensor placement better than a regular machine shop.

- Certification Standards (ISO 9001) and Quality Assurance: You should find partners who meet global quality standards like ISO 9001. This is proof that they have strict process controls, which is vital when making robotics parts with such tight measurements.

- In-House Engineering Support and Prototyping Capabilities: Working with engineers speeds up the design checking process. This is done through quick prototyping with precision CNC machining before starting full production.

- Equipment Capabilities: Multi-Axis Machining, Tight Tolerance Control: Make sure your partner uses modern multi-axis machines. These machines should be able to handle complex shapes and achieve tolerances down to ±0.01mm, a common need in today’s robotics manufacturing.

Introducing XiHui Aluminium as a Trusted Manufacturer

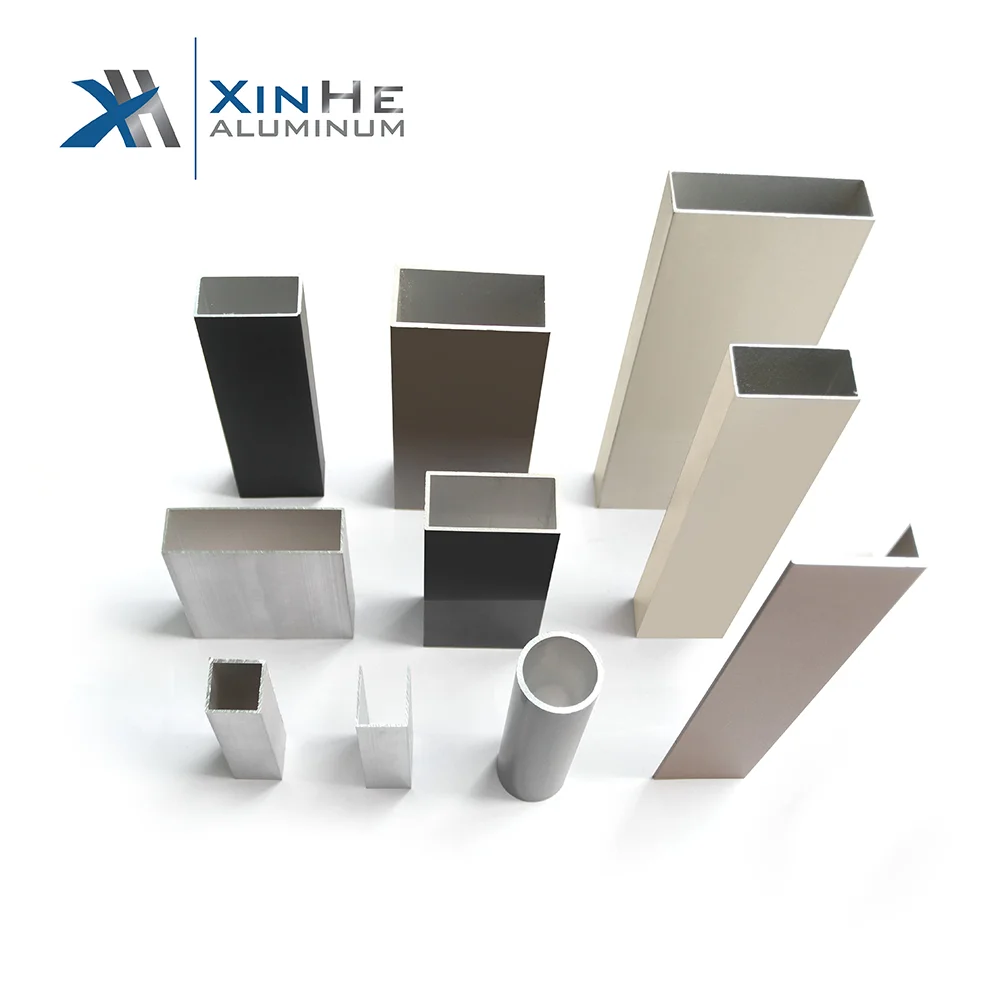

XiHui Aluminium is a great choice for a partner. The company offers skills in both extrusion and high-precision CNC work, designed for industrial uses like building robotic arms.

- Foshan XiHui Aluminium Co., Ltd. focuses on Aluminum T-Slot Profiles and industrial assembly line profiles. These are often used in things like cases for automation equipment.

- Their work includes OEM-Tailored Turning Parts and alloy profiles such as 6061/7075 aerospace-grade materials. These are offered with surface finishes like anodizing or powder coating based on what the client wants.

- With ±0.01mm tolerances, fast prototyping services, and worldwide shipping support, they provide amazing flexibility for projects of any size. This is true whether you are testing new ideas or starting a large production run.

- On top of that, their team has engineers who focus on assembly. These engineers can give assembly drawings and suggest solutions based on what a client needs. This engineering help makes your project go even smoother, from the first idea to the final delivery.

FAQs:

Q1: What makes precision CNC machining essential in robotics?

A: Precision CNC machining provides very tight tolerance control, down to ±0.01mm. This is extremely important when putting together complex robotic systems. These systems need perfect movement coordination between many axes or sensors without any alignment issues over time.

Q2: Why is aluminum preferred over steel in many robotic arm structures?

A: Aluminum has a great strength-to-weight ratio, which lowers inertia when the arm is moving. After being anodized, it’s also very resistant to rust. So, this makes it perfect for all kinds of robots, from those in indoor labs to those in outdoor industrial settings.

Q3: Can XiHui Aluminium handle custom designs with tight deadlines?

A: Yes, XiHui Aluminium is set up for quick work. For items they have in stock, orders can be ready to ship in 3-5 days. For custom jobs, a full container usually takes 25-30 days. It might take another 7-15 days if a new mold needs to be made. Their large collection of molds and efficient methods allow them to fill even custom orders quickly.