The growth of high-density electronics has sparked a big rise in need for tiny, exact parts. These small setups show up in phones, planes, and more. They demand components that are not just small. They must also meet strict standards. As gadgets get smaller and do more, reliable links like aluminum pins and sockets grow vital.

Exact machining helps meet these needs. It creates custom aluminum pieces with close limits. This boosts top performance and trust in tricky electronic builds. Swiss-Type CNC turning stands out here. It’s a special kind of CNC exact machining. It crafts detailed, small-round parts with great care.

Swiss-Type CNC turning has become a key tool for making tiny aluminum pins and sockets in tight electronic setups. Its fast speeds, many-axis control, and hold on close limits fit perfectly for custom aluminum extrusions and other fine-cut parts in the electronics world.

Overview of Swiss-Type CNC Turning Technology

Swiss-Type CNC machines differ from regular lathes. They use a sliding headstock setup. Here, the workpiece slides lengthwise through a guide bushing. Tools cut it at the same time from many spots. This brings more steadiness and care in the work.

In usual CNC turning spots, the part stays put. Tools circle it. But Swiss machines push the material through the spindle. This cuts down on bending. It allows closer limits. That’s why they shine for long, thin pieces under 32mm wide.

A main plus of Swiss-Type CNC turning is its knack for making small, detailed bits quickly. With many axes and live tools, these machines handle tough shapes in one go. Perfect for custom aluminum parts like pins and sockets in packed electronic groups.

Importance of Miniature Aluminum Pins and Sockets in Electronics

Tiny pins and sockets act as key links in crowded electronic gear. They make sure power flows smoothly between circuit bits. All while taking up little room. In small setups like wearables or check-up tools, space matters a lot. So, care counts big time.

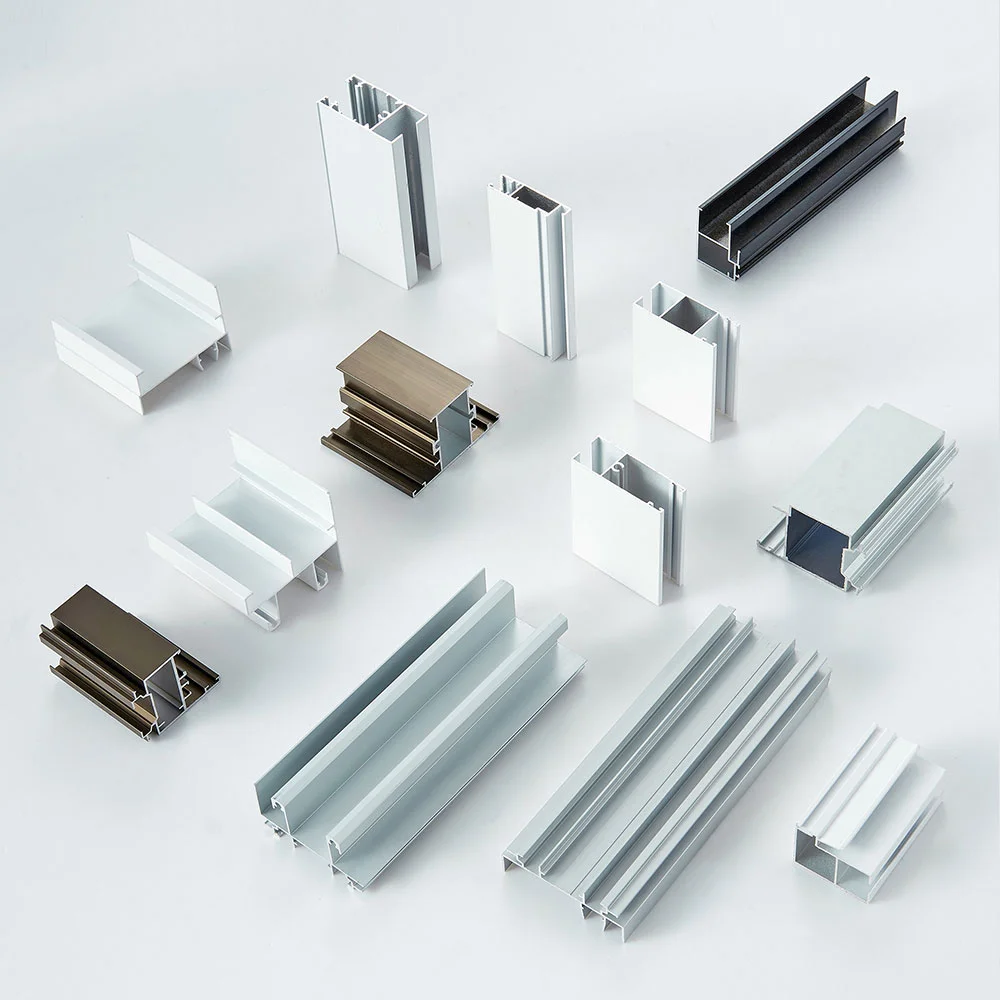

Aluminum works great for these parts. Why? It has built-in perks. Industrial aluminum profiles come from alloys mostly of aluminum. Billets heat up and squeeze out to form shapes with different cuts. This yields light but tough profiles for small jobs.

First off, its low weight fits where cutting pounds is key. Think planes or handheld gadgets. Plus, it carries heat and power well. That means smooth signal sends through wires.

Aluminum fights rust on its own. This boosts it for rough spots or medical gear that needs cleaning. What’s more, you can anodize its face. That treatment fights rust and wear. It ups strength and looks without messing up size accuracy. Vital for micro bits.

Custom Aluminum Parts for Electronic Applications

Tailoring matters a ton in high-density electronics design. Each job might call for odd sizes or limits based on what it’s for. Swiss-Type CNC turning backs this bend. Makers can tweak every bit of making. From picking raw stuff to last touches.

Finishing the surface aids both work and style. Anodizing fights rust. It also gives even shine for marks or color tags in builds. Common anodized shades like silver-white and black are easy to get. They lift function and eye appeal.

Other ways, like shining or powder cover, work too. Depending on the end spot. These boost wear fight while keeping size control tight. A must for socket joins or pin lines that need spot-on setup in CNC turning steps.

Custom Aluminum Extrusions in CNC Precision Machining

Squeezed profiles base many cut parts across fields, including electronics. Starting with industrial aluminum extrusions cuts junk and smooths flows.

These profiles slip right into CNC turning by slicing them to blanks first. Then machining kicks in. This team-up of squeeze and CNC exact machining speeds up test builds. It also scales up runs. Great for new lines or quick market jumps.

On top, making fresh molds from client sketches lets makers craft squeezes just for those plans. This pushes fresh ideas in tight electronic worlds.

Achieving Precision with CNC Machining Techniques

Holding close limits rules when working micro sizes in high-density electronics. Swiss-Type CNC machines lead here. Their stiff builds and live check systems watch tool lines non-stop. Many-axis setups let cuts happen on many sides at once. No need to shift the part. This drops build-up errors over runs.

To keep batches steady, check steps run the full cycle. Things like coordinate measuring machines (CMM), eye scan systems, and stats process control (SPC) do the job. They make sure each custom aluminum part hits the marks OEMs want worldwide.

Challenges in Manufacturing Miniature Pins and Sockets

Tech jumps help, but hurdles stay in making tiny bits from aluminum alloys.

Thermal stretch needs watch during CNC turning. Tiny slips can mess fits between pair parts at micro levels.

Tool wear bugs too. Aluminum’s soft side to steel means swaps often. Unless coated tips get smart use.

Exactness gets way tougher below 1mm wide. Common in watch sensors or body implants.

Chip clear-out trips up in fast runs. If coolant flow or pull channels in holds don’t handle it, bits scratch shines or jam gear mid-way.

Applications Across Industries Using High-Density Electronics

Tiny pins and sockets from Swiss-Type CNC turning pop up wide.

In consumer electronics—phones, pads, wearables—they power small deliver without losing link speed or trust.

Medical gear gains from custom aluminum bits. They’re body-friendly and clean easy. Fit for sensors in probe tips or cut tools that need true lines in tight spots.

Aerospace folks count on CNC exact machining for light control boxes in plane dash or sats. Shake fight matters. Space stays small.

Car makers tuck these small links into driver-help setups (ADAS), fun units, or EV pack batteries. All need strong but room-smart joins.

Introduction to XiHui Aluminium as a Trusted Manufacturer

XiHui Aluminium shines as a top supplier. They focus on industrial aluminum profiles and parts from them. Plus add-ons. Their know-how covers over 30 years. They handle all sorts of client wants around the globe.

They offer top CNC metal machining beside squeeze lines. These deliver OEM custom turned parts just per drawings. Proof of their drive for fresh-make top-notch.

With 33 years in making and selling, the firm holds tens of thousands of molds in all kinds of styles. They also craft custom molds for exact client calls. This big mold stock speeds turns even on special orders with wild shapes. Think tiny socket plans in tech spots today.

Key bits like anodized 6061/6063-T5 profiles give rust-fight fixes. Ready for tie-in to touchy spots like med labs or plane holds. Where tough holds can’t bend without hitting weight goals from design pros worldwide.

FAQs

Q1: What makes Swiss-Type CNC Turning better than conventional turning for miniature parts?

A: Swiss-Type machines give top exactness. Their sliding headstock cuts bend in cuts. Ideal for small-round custom aluminum parts high-density electronics makers need.

Q2: Why is aluminum preferred over other metals for pins and sockets?

A: Aluminum packs light weight with top heat/power carry. Plus rust fight. All must-haves for tough links that skip bulk in small electronic groups like wearables or drones.

Q3: Can XiHui Aluminium handle fully customized projects?

A: Yes. They back full tweaks. Sizes, surface shines (anodizing/shining), material types (6061/6063). Even match add-ons to your spot-on drawings. Perfect pair for OEM teams hunting steady chain links.