The Essential Role of Aluminum Heat Sinks in Modern Technology

In the world of high-performance electronics, managing heat is not just a recommendation; it’s a critical necessity for longevity and reliability. At the forefront of this thermal management are aluminum heat sinks, essential components designed to dissipate heat away from sensitive electronics. As technology advances and components become smaller and more powerful, the choice of a heat sink has evolved beyond a simple off-the-shelf purchase. Today, engineers must often choose between standard extruded parts and fully customized thermal solutions to meet specific project demands, a decision that significantly impacts both performance and cost.

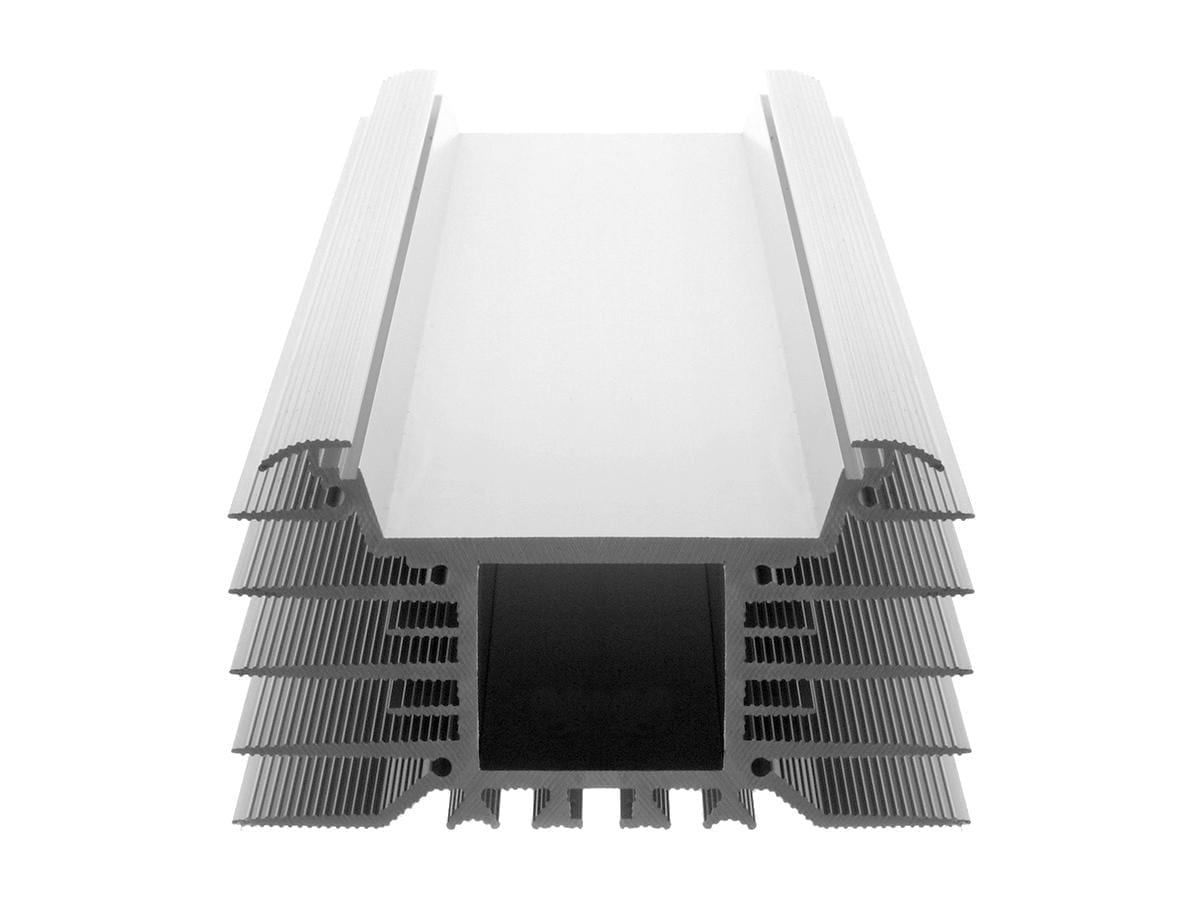

Standard Solutions: The Power of Extrusion

One of the most common and cost-effective types of heat sinks is the extruded heat sink. Created through a process called aluminum extrusion, this method involves pushing a heated aluminum billet through a die to create a specific cross-sectional profile. The result is a long piece of finned material that can be cut to any desired length. These aluminum extrusion heat sink designs are popular for their low tooling costs and rapid production times, making them an ideal choice for a wide range of general applications, from consumer electronics to standard LED heat sinks. While they are highly effective for moderate heat loads and standard-sized components, their geometry is limited to what the extrusion process can produce, which can be a constraint in more complex or space-restricted systems.

Advanced Engineering: The Precision of Custom CNC Heat Sinks

When standard solutions fall short, custom CNC heat sinks offer a leap forward in performance and design flexibility. Unlike extrusion, CNC (Computer Numerical Control) machining carves a heat sink from a solid block of aluminum, allowing for incredibly intricate and optimized geometries. A perfect example is a high-performance model featuring a unique hexagonal design. This geometry maximizes surface area for superior heat dissipation while maintaining structural integrity. Its precision-engineered ribbed fins are arranged to enhance airflow, while the lightweight premium-grade aluminum ensures top-tier thermal conductivity. The open hexagonal core provides optimal ventilation, a feature crucial for industries where reliability is paramount. Such a design demonstrates how custom CNC heat sinks can address specific thermal challenges that an extruded part cannot.

Making the Choice: Stock vs. Customized Thermal Solutions

Deciding between a standard part and a custom design comes down to the unique requirements of your application. An extruded heat sink is often the right choice for projects with standard thermal loads, ample space, and tight budgets. However, for cutting-edge electronics, high-power LEDs, or devices operating in harsh environments, customized thermal solutions are often necessary. This is where heat sink design services become invaluable. These services allow engineers to develop a heat sink tailored to precise spatial constraints, thermal dissipation needs, and airflow characteristics. This bespoke approach ensures that every aspect of the design, from fin density to material selection, is optimized for maximum efficiency, guaranteeing component stability and extending the product’s lifespan.

Partnering with Experts for Optimal Performance

Ultimately, the choice between extruded and custom heat sinks is a strategic one. While extruded profiles serve a vital role in the industry, the future of high-performance thermal management lies in specialization. By collaborating with expert custom heat sink manufacturers, companies can develop solutions that are not just components but integral parts of a sophisticated thermal strategy. Whether your project can be served by a readily available extruded profile or requires the advanced engineering of a custom CNC heat sink, understanding the strengths and weaknesses of each approach is the key to creating a successful, reliable, and efficient final product.