Modern factories and engineering teams look for structures that are steady, flexible, and simple to adjust. As these needs grow, T-slot aluminum CNC machining has become a major choice for building many types of industrial systems. These include automation lines, robotic platforms, testing benches, conveyor frames, and machine enclosures. When CNC methods are applied to aluminum extrusions, the profiles gain a higher level of accuracy and reliability. They also become easier to use in different industrial tools, fixtures, and stable work setups.

These CNC improvements give engineers stronger control over their builds. They also offer a cleaner, safer, and more organized way to assemble equipment without complicated welding. This article explains how CNC techniques upgrade T-slot profiles, how ideas turn into real parts, which operations are often used, and why choosing the right supplier helps teams build dependable and safe structures that can last for years.

Introduction to CNC Machining for T-Slot Aluminum Structures

Industrial companies often adjust their production layouts, and they need equipment that can change just as quickly. Aluminum extrusion profiles support this need, but raw extrusions alone cannot meet all engineering goals. CNC machining plays a key role here. It uses digital programs and steady cutting tools to shape the extrusion with high accuracy. By doing so, many problems like misalignment, rough edges, or incorrect hole spacing can be avoided.

CNC work also creates a smooth path from digital design to physical product. Every cut, opening, and drilled point follows the same programmed steps. The result is a reliable and repeatable process that supports advanced mechanical systems in factories, laboratories, and assembly centers.

How CNC Technology Turns Engineering Concepts Into Real Aluminum Components

Ideas from engineers usually begin with sketches or CAD drawings. These designs need a way to become solid parts. CNC machining makes this possible. It helps create parts that fit special needs, such as motor mounts, sliding rails, sensor plates, and corner brackets.

When a project starts, the usual steps are:

- Engineers provide a 2D or 3D drawing

- Technicians check the design

- The best extrusion profile is selected

- CNC steps are planned carefully

- Machining begins with digital programming

- Each completed part is inspected

This process gives designers the freedom to create many types of structures. It also makes the parts connect smoothly during assembly. No heavy welding is needed. Parts can be reused, replaced, or reconfigured anytime, making the entire system much easier to maintain or upgrade.

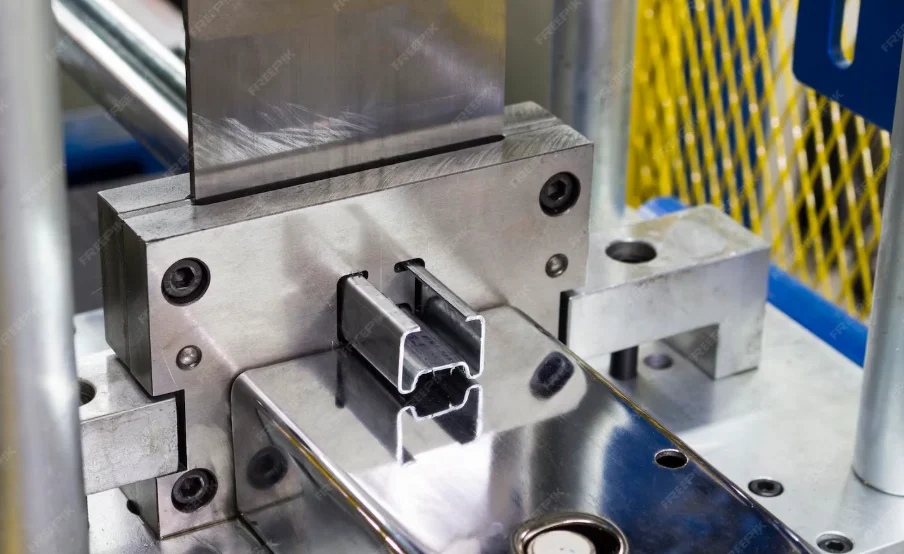

Core CNC Operations Used on T-Slot Aluminum Profiles

A short transition helps explain why the following CNC methods matter. Each machining step adds accuracy to the T-slot profile. This accuracy becomes important when building stable mechanical systems that require tight tolerances.

Precision CNC Milling

CNC milling shapes the surfaces and edges of aluminum profiles. It helps with:

- Adjusting slot width

- Flattening surfaces

- Creating cable channels

- Making small grooves or recesses

These milling steps help the profile fit better with other components, especially in high-speed or high-load systems.

CNC Drilling and Tapping

After milling, drilling and tapping create holes and threads for assembly. These steps support:

- Bolt installation

- Threaded connectors

- Sensor or panel mounts

- Accurate bracket positions

The entire structure depends on these holes. Even a small error may cause misalignment. This is why CNC drilling remains a key part of the process.

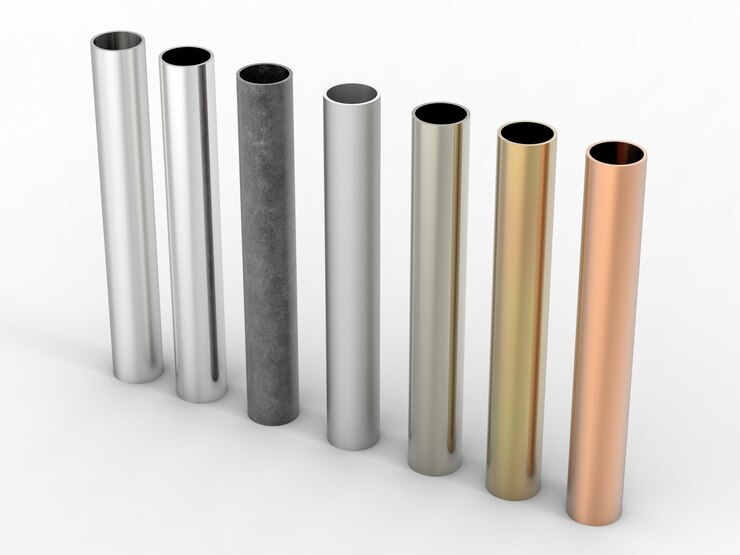

CNC Turning for Round Accessories

Some parts, especially those shaped as cylinders, need CNC turning. This method creates:

- End caps

- Base connectors

- Couplers

- Other round accessories

Turning ensures these items match the profile perfectly.

Multi-Axis CNC Work

When a design requires angled cuts or more complex shapes, multi-axis CNC machines help finish the job. They rotate the profile during machining to create unique cuts used in robotic frames or advanced industrial systems.

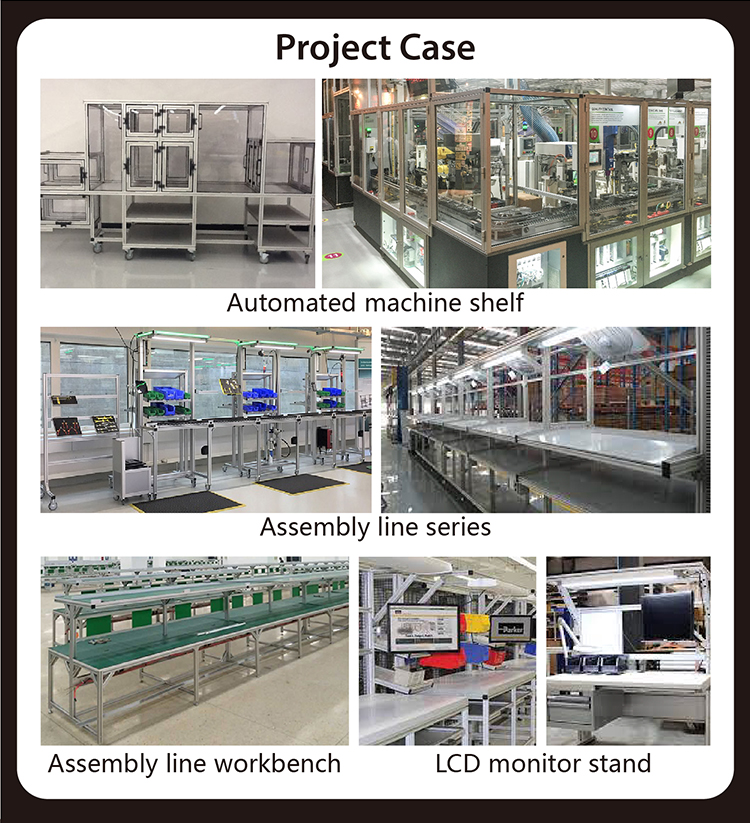

Applications Across Modern Industrial Equipment

T-slot aluminum profiles appear in more places every year. Their usefulness grows because they are light, strong, and easy to modify. CNC machining strengthens these benefits even more and allows designers to develop large systems without welding.

Common uses include:

- Automated production lines

- Conveyor frames

- Machine guarding

- Robot workstations

- Tooling fixtures

- AMR and AGV bases

- Testing and inspection machines

- Frames for 3D printers and CNC machines

img.4040 T-slot Aluminum Extrusion.webp

The 4040 T-slot Aluminum Extrusion is one of the most widely used profiles for these applications:

Here is a simple comparison that highlights its advantages:

| Feature | Steel | T-Slot Aluminum |

|---|---|---|

| Weight | Very heavy | Light and easy to move |

| Rust Resistance | Needs protection | High by default |

| Assembly | Welding required | Uses bolts and connectors |

| Flexibility | Low | Very high |

| Reuse | Not easy | Simple to reuse |

Many companies now choose aluminum because they want a cleaner workspace and faster assembly options.

Surface Finishing Options for CNC-Machined Aluminum

Before introducing the supplier, it helps to explain why finishes matter. Finishes protect aluminum from wear and also improve its appearance.

Popular options include:

- Silver anodizing

- Black anodizing

- Champagne anodizing

- Powder coating

- Brushed finishing

- Sandblasting

- Wood-grain effects

These coatings protect the profile from scratches, moisture, and repeated handling. They also allow the metal to match different industrial or commercial styles.

XiHui Aluminium: A Reliable Supplier of Aluminum Extrusion Profiles

A short transition leads into the supplier section. Choosing an experienced supplier ensures better machining results and smooth project progress.

XiHui Aluminium offers industrial extrusion profiles, CNC machining support, and custom production services for global clients. Its capabilities include:

- Accurate extrusion production lines

- CNC milling, drilling, tapping, and cutting

- Custom mold development

- Various surface treatments

- Assembly and engineering support

Customer Services and Technical Support

Before the conclusion, it helps to share how customer service improves the final result.

Service options include:

- Fast quotation and reply

- Drawing improvements

- Engineering consultation

- Sample confirmation

- Global packaging and shipping

- After-sales support

Conclusion

CNC machining improves T-slot aluminum profiles by adding accuracy to every part of the extrusion. Holes, threads, surfaces, and edges become more stable and safe for industrial use. These improvements also help companies build better systems that can be changed or expanded easily.

With strong extrusion ability and CNC skills, many complex ideas can become reliable aluminum structures used across the world.

FAQs:

Q1: What is the MOQ for CNC machining on aluminum profiles?

A: Most projects begin at 500 kg per model for new extrusion. Smaller orders may be possible when using existing profiles.

Q2: Which finishes can be used for CNC-machined T-slot profiles?

A: Common finishes include silver anodizing, black anodizing, champagne anodizing, powder coating, brushed finishing, sandblasting, and wood-grain coating.

Q3: Can customers send drawings for custom T-slot structures?

A: Yes. Teams accept 2D drawings, 3D CAD models, and samples. After review, suitable extrusion types and machining steps will be suggested.