As demand speeds up in fields like aerospace, automotive, and electronics, the need for light but sturdy and detailed parts has turned aluminum extrusion into a vital production method. This is where tailored CNC machining steps in as crucial. It lets makers improve extruded aluminum shapes with exact cuts, narrow tolerances, and tricky forms that extrusion alone cannot reach.

For example, a heat sink featuring detailed fins or a robot frame needing ±0.01mm accuracy shows how CNC follow-up work changes basic extrusions into ready-to-use pieces. Sectors that count on good heat flow and solid build—such as automation and green energy—gain a lot from this combined method. It blends extrusion’s speed with machining’s precision to create parts that perform well under tough conditions.

A firm that shows this blend well is this CNC aluminum machining service provider. They provide ISO 9001-approved CNC skills for top-quality alloys like 6061 and 7075. Their work hits tolerances as close as ±0.01mm. With modern gear and a quick-response design group, XiHui Aluminum make the path from idea to big runs smooth and efficient. Clients often praise how this setup cuts time and waste in projects.

Can All Aluminum Extrusions Be Bent Successfully?

While aluminum extrusion is a versatile process for creating complex cross-sectional profiles, the subsequent bending of these shapes is not universally guaranteed. Successful bending hinges on a careful interplay of material properties, geometric design, and manufacturing technique. Without proper consideration, processes like CNC machining may be compromised by defects introduced during forming. This section explores the foundational factors determining bendability.

How Does Alloy Composition Influence Bendability?

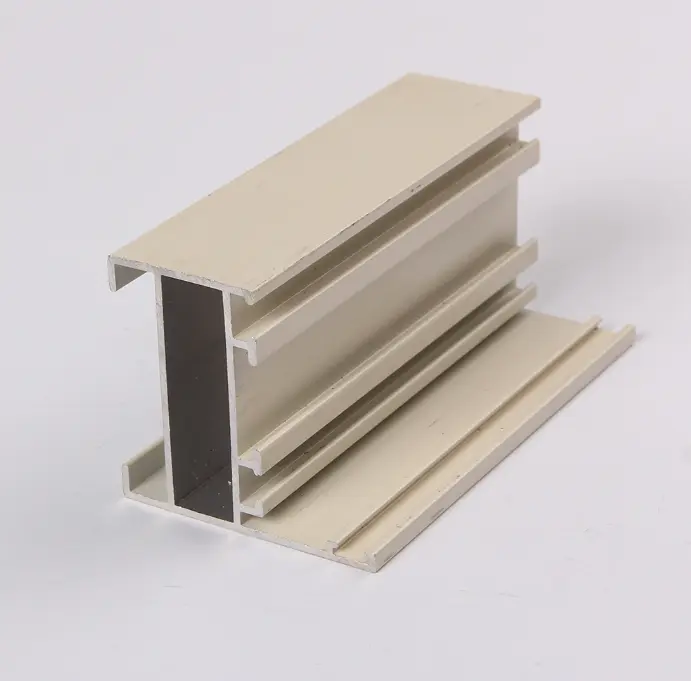

Choosing the right alloy forms the base when checking if an extruded aluminum shape can bend without harm. Various alloys show different physical traits. The 6000 series, particularly 6061 and 6063, gets picked often because of their fine shaping ability, rust resistance, and fair strength. Industrial aluminum profiles are aluminum-based alloy materials. Aluminum billets are heated and extruded to produce aluminum materials with various cross-sectional shapes; however, differing proportions of added alloys result in industrial aluminum profiles with varying mechanical properties and application fields.

Compared to 6061, 6063 feels softer and stretches more, so it fits better for sharp bends. Meanwhile, alloys such as 7075 offer much greater power but stretch less, which raises the chance of breaks when shaped. Engineers must weigh these traits early to avoid issues later. In practice, this choice affects not just bending but also how the part holds up in real use.

What Role Does Temper Condition Play in Bending?

The temper label shows the heat process state of aluminum, and it directly shapes how well it bends. Gentler tempers like T4 make cold shaping simpler. Harsher ones, such as T6, tend to split under pressure unless warmth is added. For vital uses, items shaped in the T4 state can be aged again to T6 afterward. This way, they regain power lost in the process. Such steps help keep a good mix of easy handling and strong output. It ensures the final product meets strict specs without extra risks.

How Does Profile Geometry Affect Deformation?

The shape of the cross-section stands as another main factor in how well it bends. Even wall thickness spreads stress evenly as it bends. Still, shapes with uneven walls or heavy ribs might face focused stress spots. The overall dimensions of the profile are standard market sizes, but the hole spacing within the profile is critical for assembly.

What Are the Best Methods to Bend Aluminum Extrusions?

Once material and design parameters are established, selecting the optimal bending method is critical for achieving precision and preserving structural integrity. The choice between cold and hot forming techniques, and the use of supporting tooling, depends heavily on the specific application requirements and the limitations of the aluminum profile itself.

When Is Cold Bending Appropriate?

Methods for cold bending, including roll bending and rotary draw bending, suit aluminum in mild states well. They give strong command over curve size and arc. However, care is key to skipping surface splits or hidden stress piles. Tools like mandrels or wiper dies help cut down on twists in close bends. These choices work best for straightforward jobs where heat might complicate things. Overall, cold methods keep the process quick and tool-friendly.

Why Choose Hot Bending for Certain Applications?

For thicker sections or tough states, using heat while bending lowers inner pushback. This lets shapers form items that might snap in cold tries. Even warmth spread avoids grain spread or weak spots in one area. Heat pattern devices keep steady results across the whole piece. In tough cases, this approach opens up options that cold bending cannot match. It proves useful in heavy-duty setups where strength matters most.

How Does Mandrel-Assisted Bending Improve Accuracy?

When size precision and build soundness top the list—like in health or flight parts—mandrel-aided bending turns vital. The mandrel holds the inside curve steady, stopping cave-ins or too much thinning. It suits slim-walled shapes or those needing sharp curves without shape twists. This technique shines in high-stakes fields. By adding support, it ensures parts stay true to plans, which cuts rework and boosts trust in the output.

How Can Structural Strength Be Preserved Post-Bending?

The act of bending inevitably alters the material’s state. To ensure the final component meets performance specifications, proactive analysis and post-processing treatments are essential. This phase focuses on managing the changes induced by deformation to guarantee reliability in the finished part.

What Is the Role of Stress Analysis?

FEA, or Finite Element Analysis, models stress spread during and after bending. It spots weak areas ahead of time. Using FEA right at the start lets designers adjust wall sizes or tweak shapes to ease high stress points. Thus, the end item keeps its weight-handling skill despite the changes. This tool proves invaluable for complex designs. It helps predict outcomes and refine plans, leading to safer, more reliable components that last longer in service.

Do Mechanical Properties Change After Bending?

Indeed, they do. Cold shaping often sparks local hardening from work—boosting power yet cutting stretch in the curved spot. This shift might help or hurt based on the job. To keep even results, annealing to ease stress or re-heating to set the temper often follows bending. Such follow-ups restore balance. They ensure the part performs steadily across its whole form, meeting needs without surprises.

What Quality Control Practices Ensure Reliable Bending?

Tests without harm, such as ultrasonic checks or dye leak scans, find inner faults added in shaping. Plus, CMMs confirm bent sizes stay in the allowed ranges. At this CNC profile machining, strict CMM checks and finish reviews guarantee steady quality in big lots. These steps build confidence. They catch issues early, so products reach users in top shape, ready for demanding roles.

What CNC Machining Capabilities Support Advanced Bending Requirements?

Bent extrusions often require precise secondary machining to become functional components. Advanced CNC capabilities are therefore critical for adding features, achieving final dimensions, and ensuring assemblies fit perfectly. This support transforms a bent shape into a finished, high-performance part.

How Does Equipment Impact Performance?

Shops with 5-axis CNC setups bring top flexibility in cutting fancy forms on pre-shaped extrusions. Modern CNC gear hits ±0.01mm closeness with tasks like turning, milling, drilling, tapping, and etching. These prove key when adding slots, sinks, or fit points to bent areas. Such tools handle curves smoothly, which flat machines might struggle with. In the end, better gear means faster work and fewer errors, aiding tough projects across industries.

Can Customization Be Achieved From Any Input Format?

Certainly. Help comes from direct feeds from CAD types like STEP, DWG, or DXF files. Or, real samples get scanned backward. This range speeds up test builds and eases shifts to full runs. No matter if it’s five test units or thousands in bulk, scaling fits the need. Providers like these adapt quickly, turning ideas into reality without format hurdles. It keeps workflows fluid and client-focused.

What Quality Frameworks Are in Place?

A full system for quality covers size checks with CMMs, roughness scans (Ra ≤ 0.8µm), and rule follows for RoHS/REACH in finishes like anodizing or powder coating. ISO 9001-backed steps assure steady repeats in every phase. These measures cover all bases. From raw checks to final packs, they uphold high marks, giving peace of mind to buyers in global markets.

Which Industries Are Supported?

From flight mounts to LED coolers, this helps firm up many areas needing aluminum bits with fancy shapes and strict function calls. Their solid grasp of material ensures the best paths for each case. Whether in fast-paced auto lines or precise med tools, they tailor-fit. This wide reach shows their skill in meeting diverse needs with reliable results every time.

FAQ

Q1: Can aluminum extrusion be bent without cracking?

A1: Yes, if the correct alloy (e.g., 6063), temper (e.g., T4), geometry design (uniform walls), and suitable forming technique (e.g., mandrel-assisted bending) are used.

Q2: What is the smallest batch size I can order for CNC-machined extrusions?

A2: The minimum order quantity typically starts at 10 pieces per design when standard materials are used.

Q3: Which surface finishes are available after machining bent extrusions?

A3: Finishes include anodizing (clear/hard/color), powder coating, sandblasting, electroplating, polishing, and mill finish based on application needs.