- Home

- >

- News

- >

- Industrial News

- >

- 9 TYPES OF ALUMINUM TUBES

9 TYPES OF ALUMINUM TUBES

9 TYPES OF ALUMINUM TUBES

What are the different types of aluminum tubes?

Seamless Aluminum Tubes

Welded Aluminum Tubes

Drawn Aluminum Tubes

Extruded Aluminum Tubes

Finned Aluminum Tubes

Coiled Aluminum Tubes

Square Aluminum Tubes

Rectangular Aluminum Tubes

Hollow Aluminum Tubes

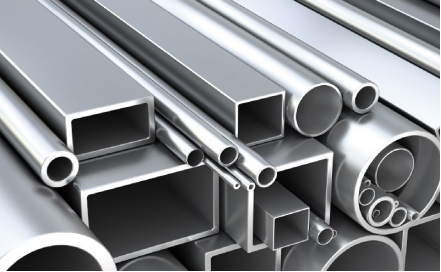

Aluminum tubes are widely used in various industries, including construction, aerospace, automotive, and manufacturing. They offer many benefits, such as being lightweight, corrosion-resistant, and easily recyclable. However, not all aluminum tubes are created equal, and they come in different types. In this blog post, we will explore the various types of aluminum tubes and their applications.

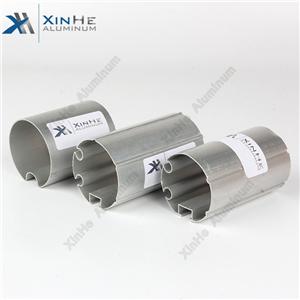

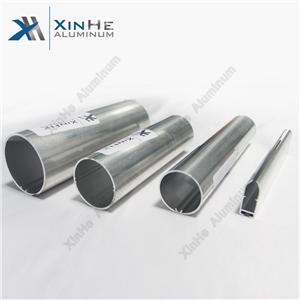

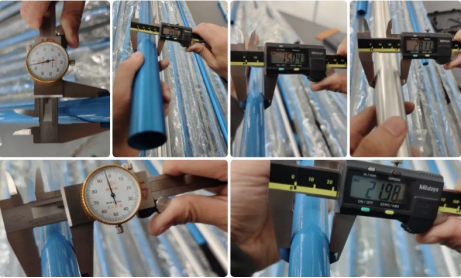

Seamless Aluminum Tubes

Seamless aluminum tubes are made by drawing a solid aluminum billet through a die to create a hollow tube. They have no seams or welds, which makes them stronger and more reliable than welded tubes. Seamless aluminum tubes are commonly used in high-pressure applications, such as hydraulic systems, heat exchangers, and air conditioning systems. They are also used in the aerospace industry for fuel and hydraulic lines.

Welded Aluminum Tubes

Aluminum tubes that are welded together from two or more pieces of aluminum are known as welded aluminum tubes. While they are more affordable than seamless tubes, they are not as robust. Welded tubes are frequently used in applications that do not require high pressure, such as furniture, fences, and light fixtures. Additionally, they are used in the automotive industry for exhaust systems.

Drawn Aluminum Tubes

Drawn aluminum tubes are made by drawing a solid aluminum rod through a die to create a hollow tube. They have a smooth surface finish and are used in applications that require a high level of precision, such as instrumentation, telecommunications, and aerospace. Drawn aluminum tubes are also used in the medical industry for catheters and other medical devices.

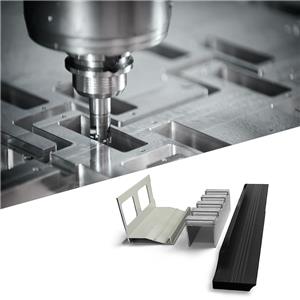

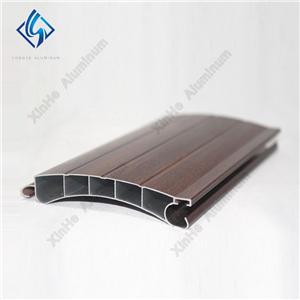

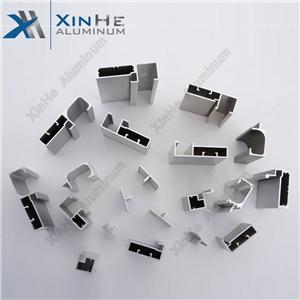

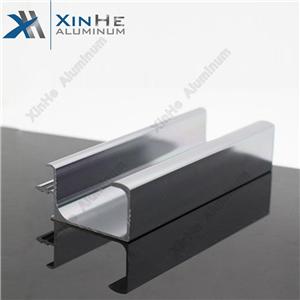

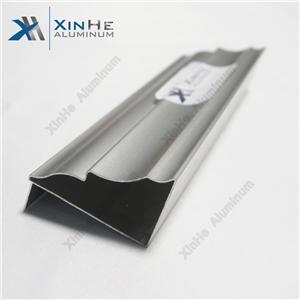

Extruded Aluminum Tubes

Extruded aluminum tubes are produced by pushing heated aluminum billets through a die to form a hollow tube. With a uniform cross-section, they are ideal for applications that demand a high degree of structural integrity, such as construction, transportation, and marine applications. In addition, extruded aluminum tubes are employed in the automotive industry for structural components and radiator supports.

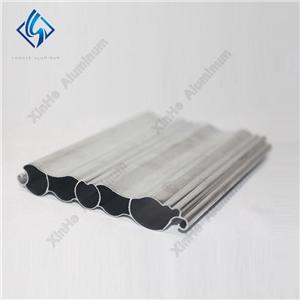

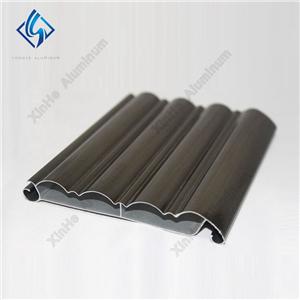

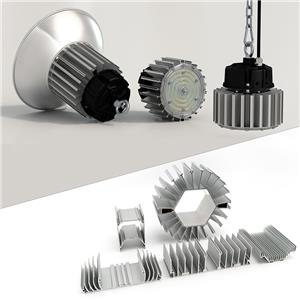

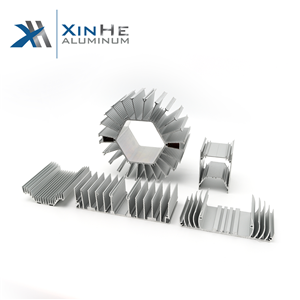

Finned Aluminum Tubes

Finned aluminum tubes are used in heat transfer applications. They have fins on the outside of the tube that increase the surface area and improve heat transfer efficiency. Finned aluminum tubes are commonly used in air conditioning and refrigeration systems, as well as in heat exchangers for the aerospace and automotive industries.

Coiled Aluminum Tubes

Aluminum tubes that are coiled into a smaller diameter coil are known as coiled aluminum tubes. They are utilized in applications that require flexibility and easy installation, such as refrigeration and air conditioning systems. Coiled aluminum tubes are created by coiling a lengthy section of aluminum tubing. Furthermore, they are used in the medical industry for medical devices such as catheters.

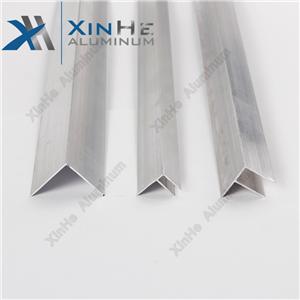

Square Aluminum Tubes

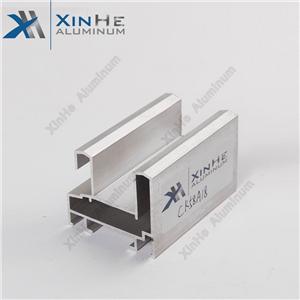

Square aluminum tubes are used in applications that require a high level of structural integrity, such as construction, transportation, and marine applications. They have a square cross-section and are used as structural components for frames, supports, and rails. Square aluminum tubes are also used in the automotive industry for suspension components and body structures.

Rectangular Aluminum Tubes

Rectangular aluminum tubes are akin to square tubes, with the distinction being their rectangular cross-section. While they can be used in similar applications to square tubes, they are better suited for applications requiring a wider profile, such as trailer frames and boat docks.

Hollow Aluminum Tubes

Hollow aluminum tubes are used in applications that require a lightweight and rigid structure, such as antennas, flagpoles, and furniture. They have a hollow center and are commonly made from extruded aluminum. Hollow aluminum tubes are also used in the automotive industry for shock absorbers and steering components.

Benefits of Aluminum Tubes

Aluminum tubes offer numerous benefits, making them a popular choice across a wide range of industries. Firstly, aluminum is lightweight and has a high strength-to-weight ratio, making aluminum tubes an ideal choice for applications that require a strong yet lightweight material, such as aerospace, transportation, and construction. Additionally, aluminum is highly corrosion-resistant, providing excellent protection against rust and other forms of corrosion. This makes aluminum tubes a suitable choice for outdoor and marine applications.

Secondly, aluminum is an excellent conductor of heat and electricity, making it a popular choice for heat exchangers, radiators, and other thermal management applications. It also has good thermal and electrical conductivity, allowing for efficient heat transfer and electrical conductivity. Furthermore, aluminum is malleable and can be easily formed into various shapes, making it a versatile material for use in tubes, pipes, and other structures. Lastly, aluminum is recyclable, making it an environmentally friendly option for various applications.

Key Takeaway

There are many types of aluminum tubes, each with its unique properties and applications. Here at XIHUI Aluminum, our windows are made from high-quality aluminum. Contact us here to learn more about our products.