- Home

- >

- Products

- >

- Roller Shutter Aluminium Profile

- >

- Aluminium Profile For Roller Shutters

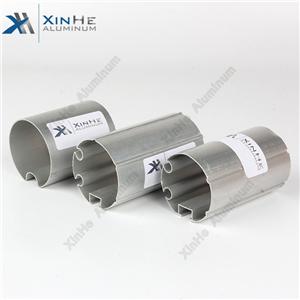

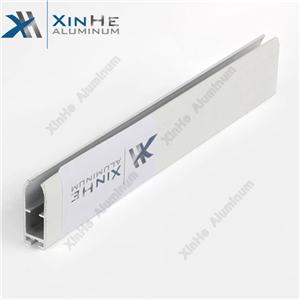

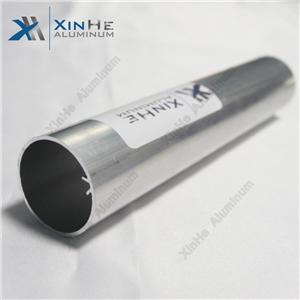

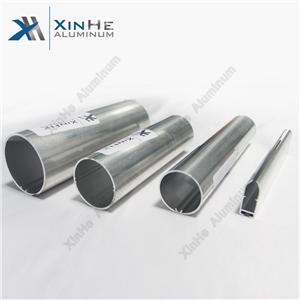

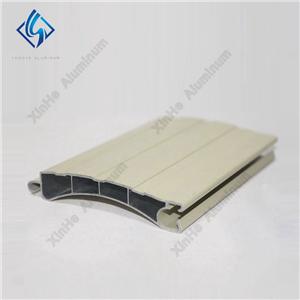

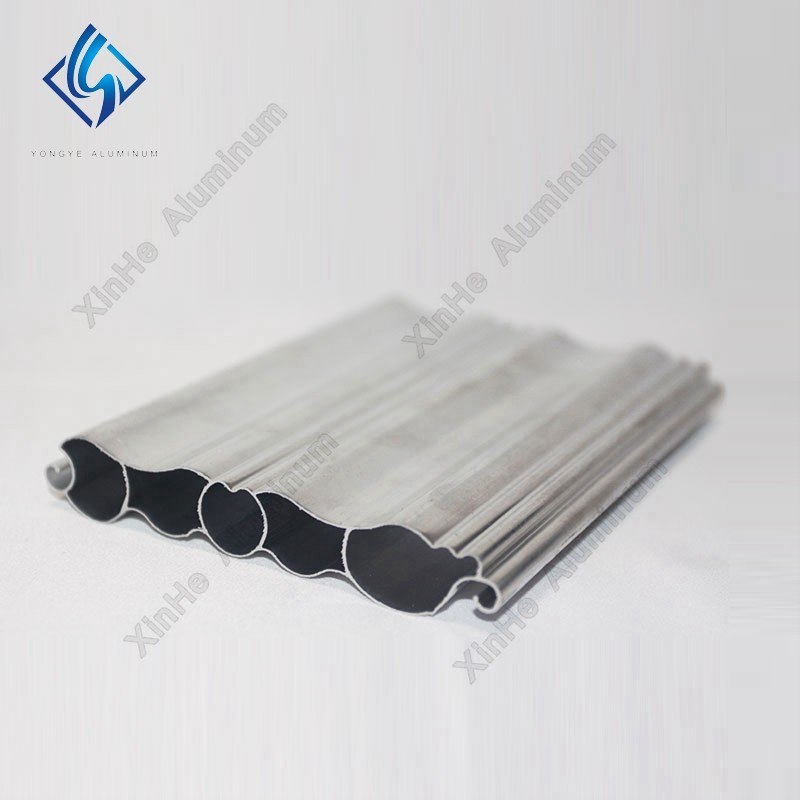

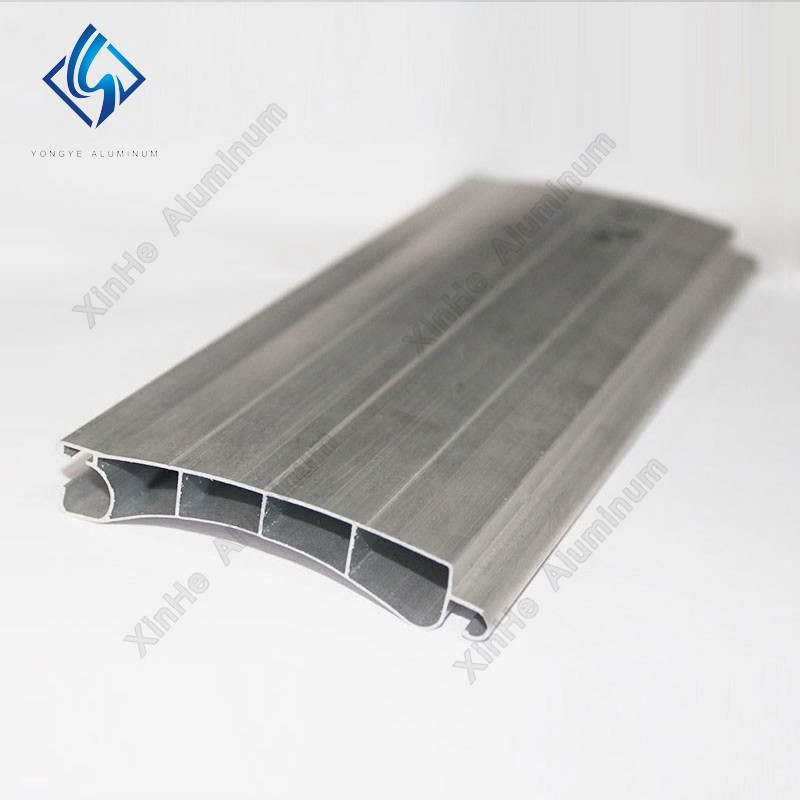

Aluminium Profile For Roller Shutters

Brand :Xinhe

Product origin :Foshan,Guangdong,China

Delivery time :10-15 days

Supply capacity :2000 Ton/Tons per Month

Why choose us?

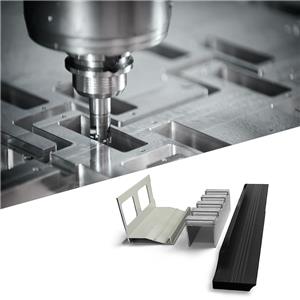

1.Offer OEM&ODM.

2.Thickness as thin as 0.4mm.

3.Fast delivery for 10-15 days.

4. free samples,please contact us.

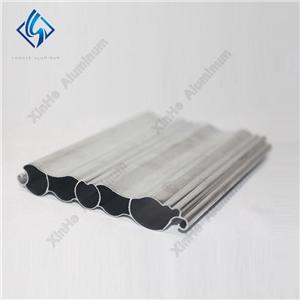

Aluminum profile Feature:

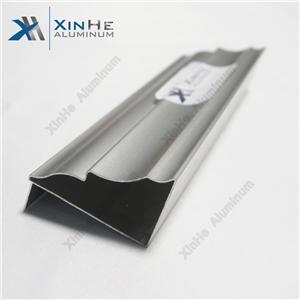

1.Reduced heat loss, lower energy costs.

2.roller shutters are smooth, quiet and easy to operate.

3.Protection against cold, sun, noise and prying eyes.

4.It also retains its shape and colour better than PVC. Aluminium roller shutters also provide eff ective anti-burglary protection.

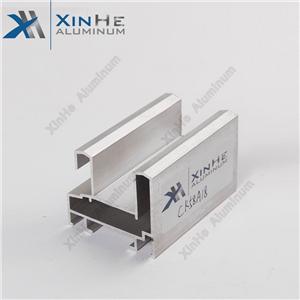

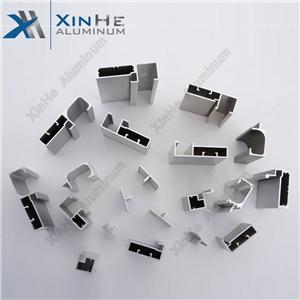

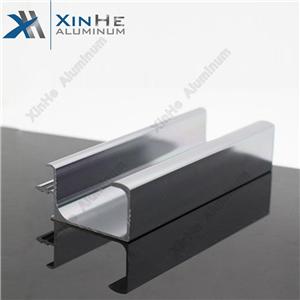

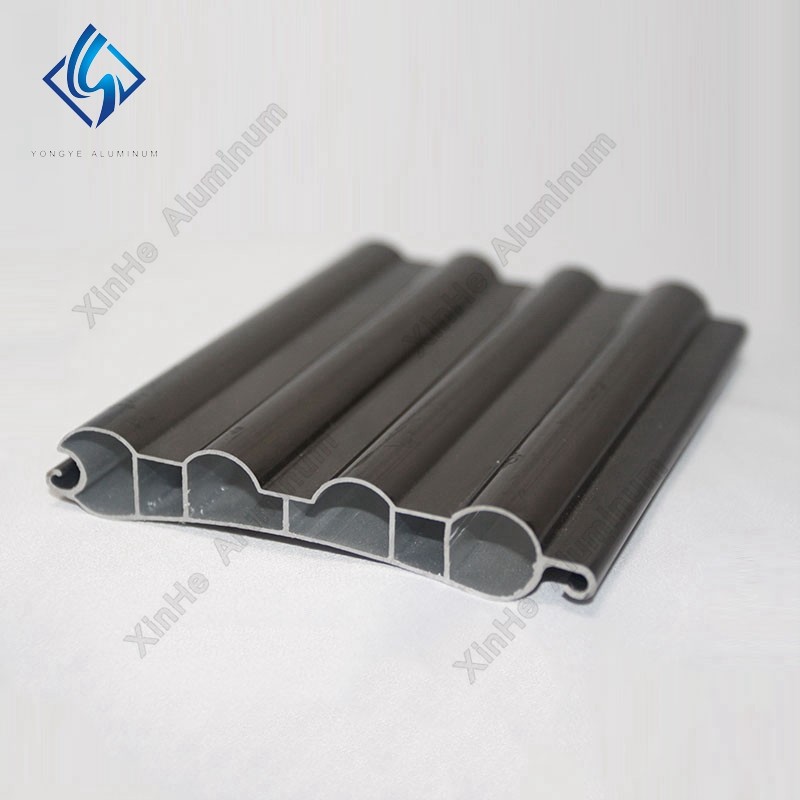

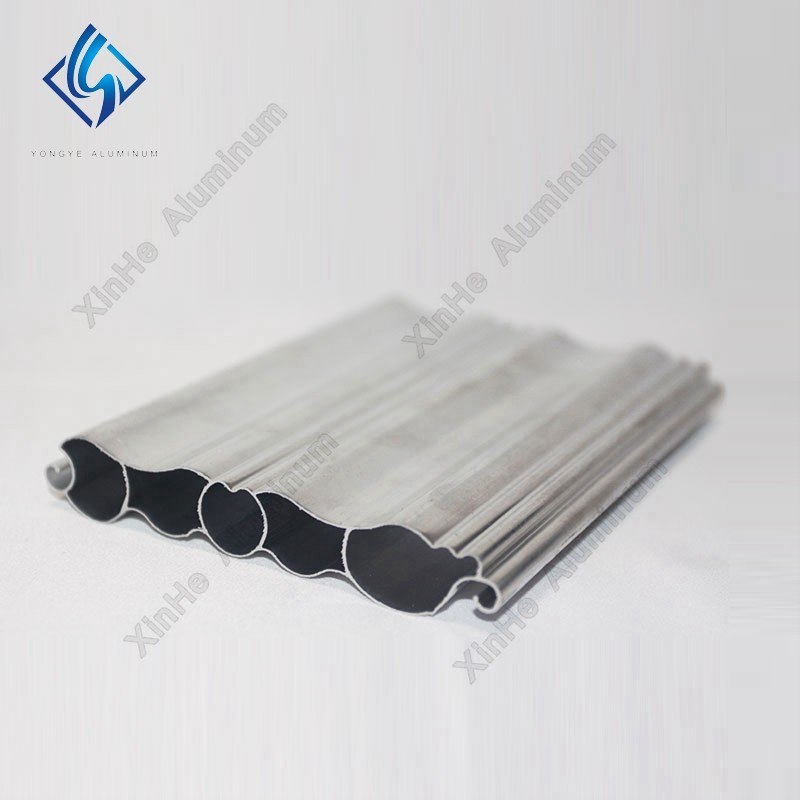

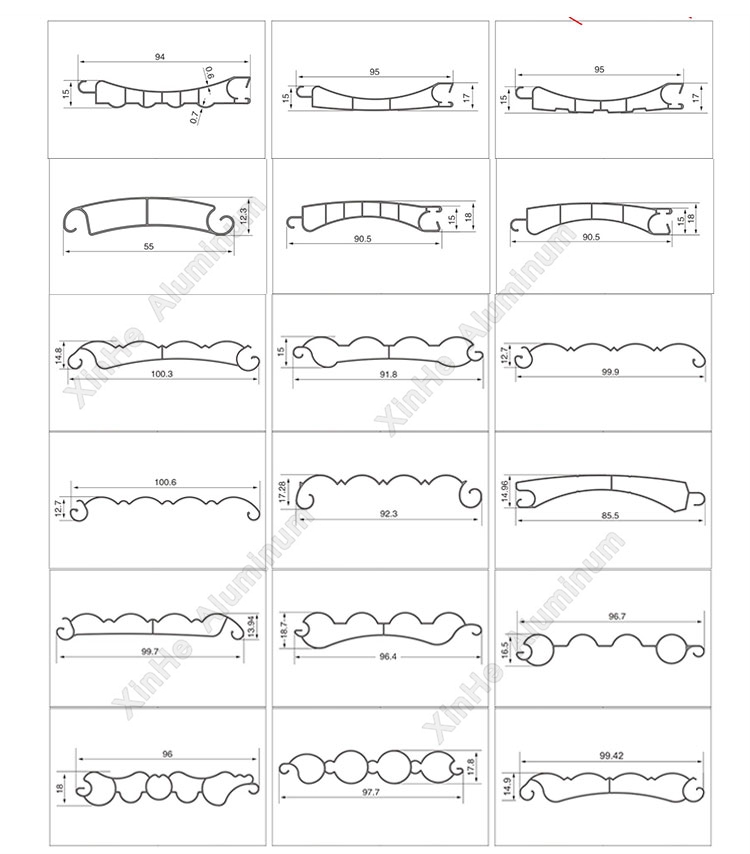

Aluminium Profile For Roller Shutters

| Product Information | |

| Grade | Aluminium alloy 6061 6063 |

| Material | Aluminium alloy T5/T6 |

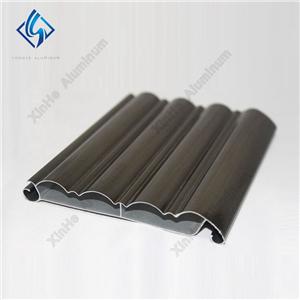

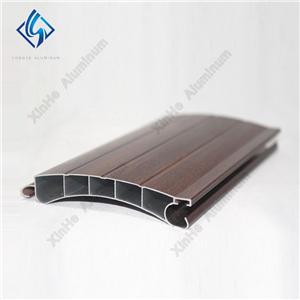

| Color | Powder coating white, bronze, charcoal and anodised natural etc |

| Surface treatment | Mill finish,powder coating, andised etc |

| Length | 5.8m/5.85m/customization |

| Thickness | 0.4 mm and up |

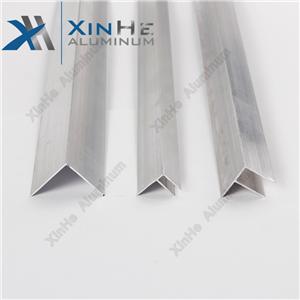

| Application | Aluminium window and door |

| Certificate | SGS,SONCAP,ISO 9001:2008,ASTM |

Feature | Good wear and corrosion resistance. Smoothness,attractive and elegant looking to meet your perferences. Simple and easy for instanllation. |

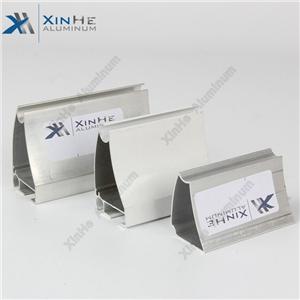

Roller shutters are permanently exposed to the elements. A big challenge, particularly in view of climate change: extreme situations, such as heat waves, storms and changing weather patterns. This places increasing demands on materials and building facades. Aluminium provides an advantageous, high grade material that guarantees durability and longer product life. It also retains its shape and colour better than PVC. Aluminium roller shutters also provide effective anti-burglary protection.

FAQ

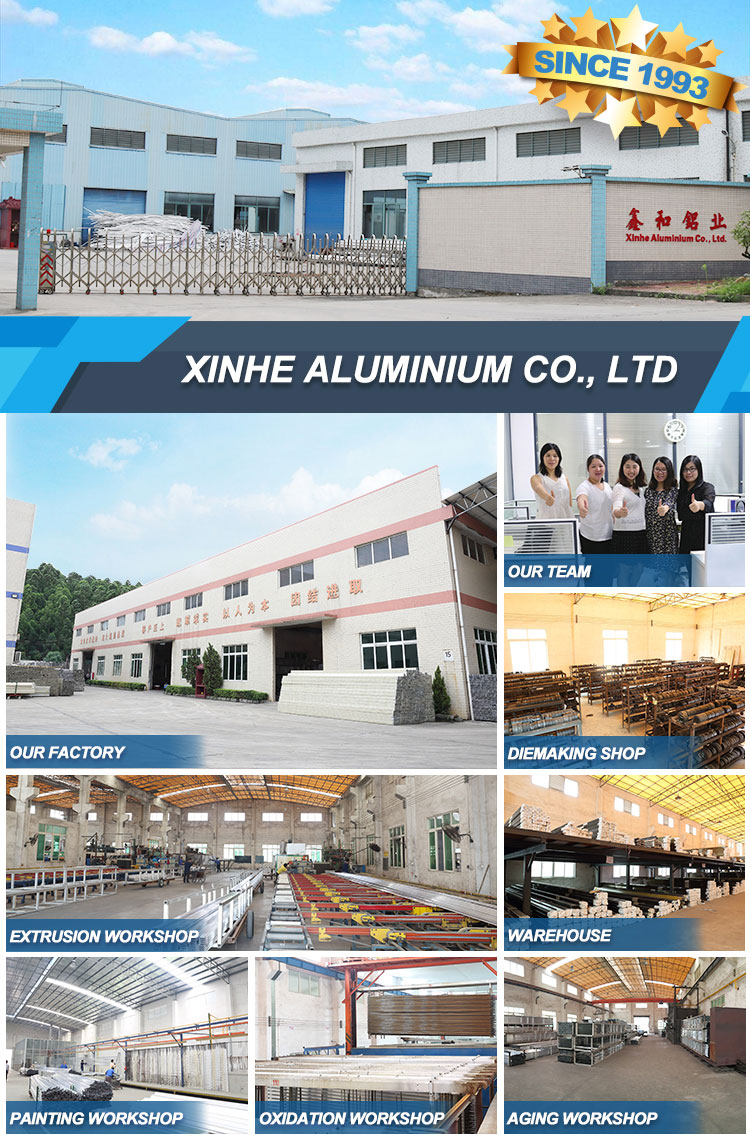

Q1: Are you a factory or trading company?

A1: We're a self -own factory, can provide one-stop service for our customer, from materials to various surface treatments, and from technical sales to shipping and to after-sales, so we can save the cost for client, control the quality and lead time, provide the best services .

Q2: What's the production time for new molds and mass production?

A2: 7-10 days to open the new moulds, mass production takes around 20-25days for one 20 GP, 25-30days for one 40HQ, can process urgently if need.

Q3: What is the payment term?

A3: Telegraphic Transfer (T/T) and Letter of Credit (L/C) are acceptable.

Q4: Can you send me samples?

A4: Yes, please feel free to contact us via email or phone with them.