- Home

- >

- News

- >

- Industrial News

- >

- Heat Treatment Process Of Aluminum Profile

Heat Treatment Process Of Aluminum Profile

Heat Treatment Process Of Aluminum Profile

The heat treatment process of aluminum profiles is an extremely important part of the processing process

of aluminum profiles. Excellent heat treatment process can improve the performance and quality of

aluminum profiles, while reducing the difficulty of profile processing and reducing costs. Therefore,

in the processing of aluminum profiles, the heat treatment process must be fully paid attention to.

This paper will discuss the heat treatment process of aluminum profiles from the aspects of heat

treatment classification, heat treatment process flow, and properties of aluminum profiles after

heat treatment.

First, aluminum profile heat treatment classification

The heat treatment of aluminum profiles can be divided into two categories: solution treatment and

aging treatment. Solution treatment means that the aluminum profile is maintained at a high temperature

state for a period of time to promote the dissolution of alloying elements in the aluminum matrix.

After solution treatment, the hardness, strength, plasticity and other properties of aluminum profiles

will be improved. Solution treatment can be carried out alone or in combination with aging treatment,

which will give better results.Aging treatment refers to the rapid cooling of aluminum profiles and storage in a low temperature

environment after solution treatment, so that the alloying elements inside the metal crystal precipitate

and migrate, forming a precipitate of a certain size, distribution and shape. Since the precipitate hinders

the deformation of the metal crystal, the hardness, strength, tensile properties, etc. of the aging treated

aluminum profile will be improved.

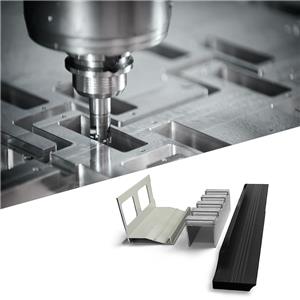

Second, the heat treatment process of aluminum profiles

The heat treatment process of aluminum profiles can generally be divided into four steps:

1. Heating. Aluminum profiles need to be heated at a certain temperature to promote the dissolution

of the elements. The heating temperature is generally determined according to different aluminum

profiles and alloying elements. The heating time also needs to be determined according to factors such

as heating temperature and the size of the aluminum profile.

2. Heat preservation. Thermal insulation refers to keeping the aluminum profile at a certain temperature

for a certain period of time, allowing the elements to fully dissolve in the aluminum matrix. The holding

time depends on the different aluminum profiles and alloying elements.

3. Cooling. The solution-treated aluminum profile needs to be cooled quickly so that the elements inside

the metal crystal are not dispersed and precipitated again, so as to ensure the subsequent aging

treatment effect.

4. Timeliness treatment. Aging treatment is to control the temperature and time to make the precipitate

inside the aluminum profile metal crystal reach a certain specification size, form a large precipitate to

hinder the displacement and deformation of the crystal, and improve the hardness, strength, tensile

performance of the aluminum profile. The aging time and temperature also need to be determined

according to different aluminum profiles and alloying elements.

Third, the performance of aluminum profiles after heat treatment

Excellent heat treatment process can greatly improve the hardness, strength, plasticity and other properties

of aluminum profiles, so that aluminum profiles have better corrosion resistance, wear resistance, high

temperature resistance and other characteristics. The improvement of the performance of aluminum

profiles after heat treatment is also related to factors such as the size, shape, and aluminum alloy

content of aluminum profiles.

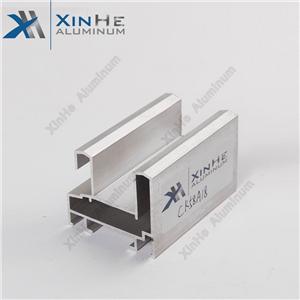

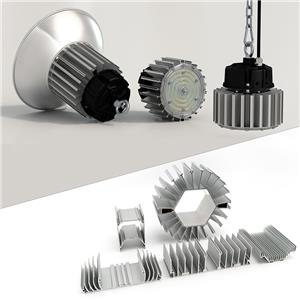

For example, in the aerospace field, high-strength, high-plasticity, high-hardness aluminum profiles are

widely used in aircraft fuselage, engine, flaps, skin and other important parts, which can improve the

bearing capacity and safety of materials. Similarly, in the fields of construction, motorcycles, electronic

communication equipment, railway vehicles, etc., the superior performance of aluminum profiles can

also be used to improve product performance and quality and reduce production costs.

In short, the heat treatment process of aluminum profiles is of great significance, which can greatly

improve the performance and quality of aluminum profiles and expand the application field of aluminum

profiles. Therefore, when selecting aluminum profiles, we should not only pay attention to the selection

of materials, but also pay attention to the selection of heat treatment process and the evaluation of

treatment effects to improve the cost performance of products.