- Home

- >

- News

- >

- Industrial News

- >

- T Slot Aluminium

T Slot Aluminium

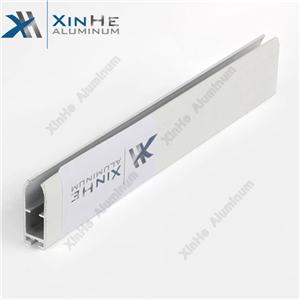

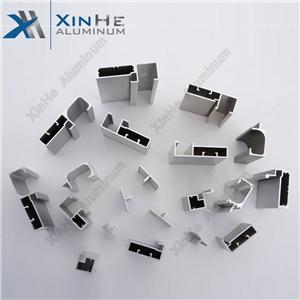

T Slot Aluminium Extrusions

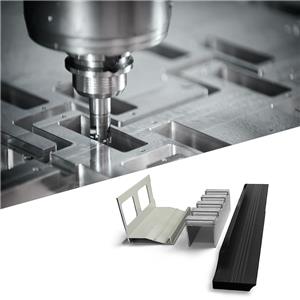

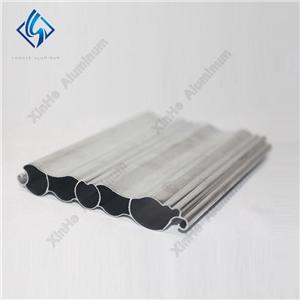

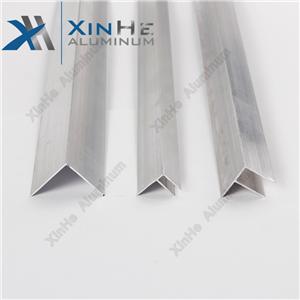

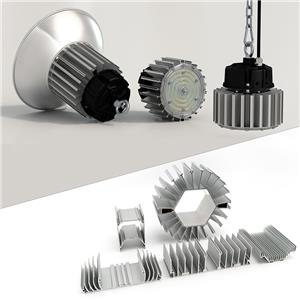

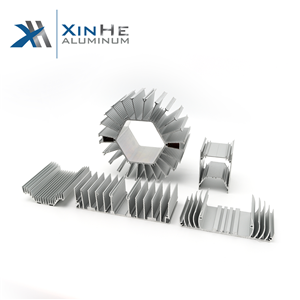

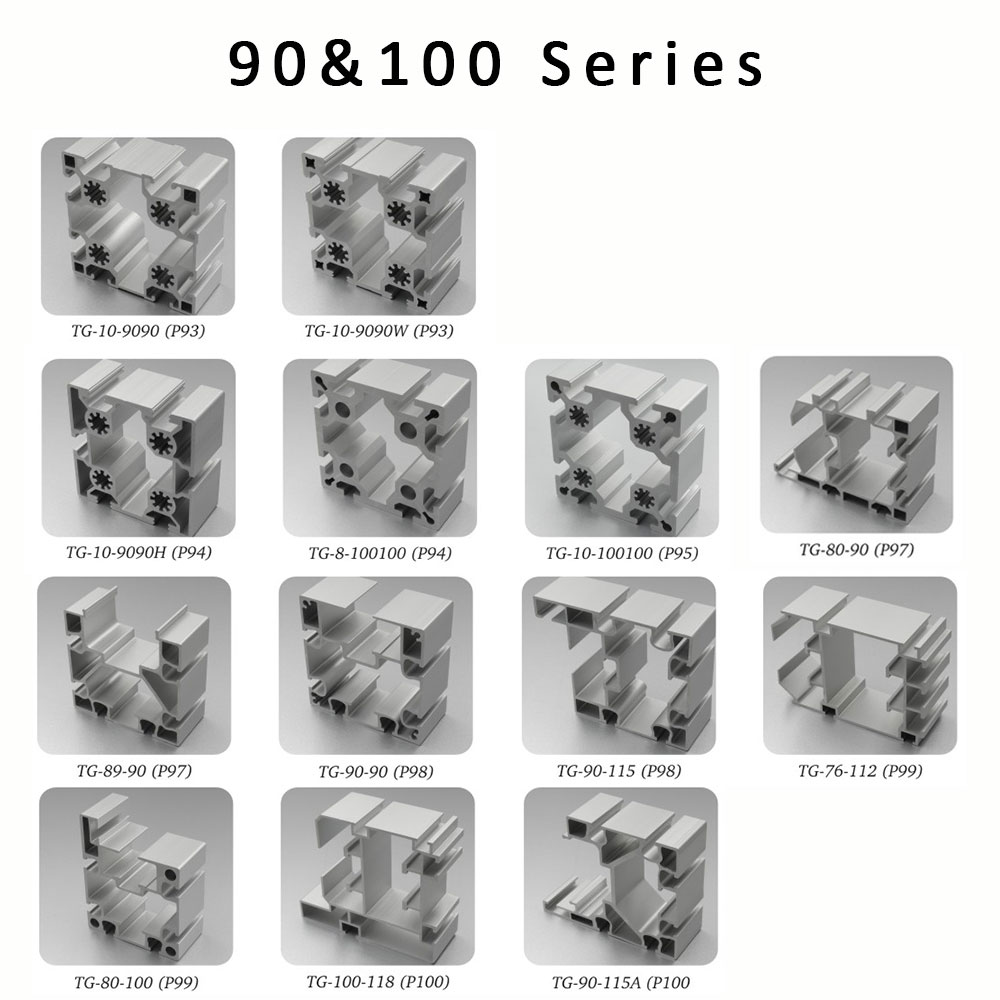

The aluminum extrusion process allows for standard and intricate profile cross sections for use in a wide range of applications. Different aluminum extrusion shapes are important in enhancing accuracy and longevity in structures. There are several parameters affecting the efficiency of aluminum profile shapes like the outer contour, thickness ratio, surface area and other specifications.

The most popular shapes are the standard round, square, channels and angles. Nevertheless, due to the versatility and variety of alloys, extruders have flexibility when it comes to the cross-section options.

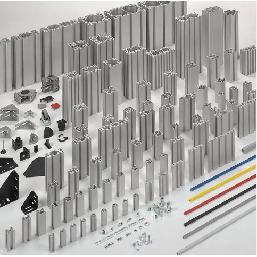

The T slot modular framings are used in connecting applications for both small scale and industrial engineering projects.

V slots are better quality and are popular in linear motion framing applications. The varying ‘T’ and beveled edges of these extrusions allow for different applications. Let’s explore key differences between the T slot vs V Slot aluminum extrusions and more.

1. T-Slots

Definition And Function

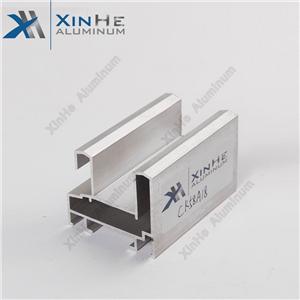

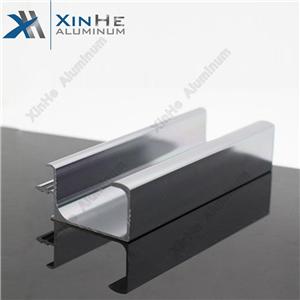

T slots are not standard aluminum extrusions; however, this does not affect their popularity. As the name implies, they are modular designs with groovings that make up an overall structure resembling a T.

The ectangular length of these extrusions can be customized for use in connecting small scale structures and assembly of advanced machinery.

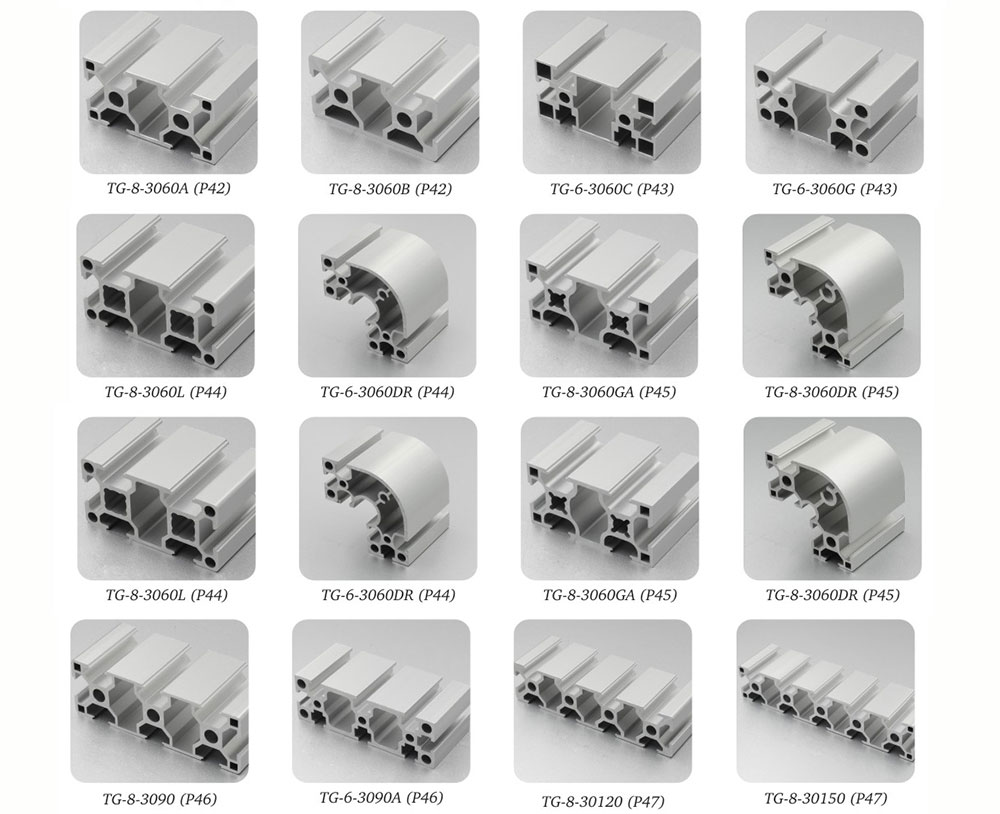

Types of T Slot Extrusions

T- Slot design options are endless. Nevertheless, there are five main categories of these extrusion, which are:

Series 20

The connecting method of this type is similar to other T slot series; however, the size is significantly smaller. You can use these T slots for small sized machinery, and lightweight framings. The most popular dimensions for this series are the 20*20 and 20*40. It allows for crisp corners and is ideal for custom projects.

Series 30

One key advantage of this series is the high tensile strength. The 30*30 dimensions mean that it has four 30mm T slots. It has different designs ranging from Super light to heavy. It allows for a variety of fasteners and allows for high pressurization. They are suitable for applications like average load structures and lightweight framings.

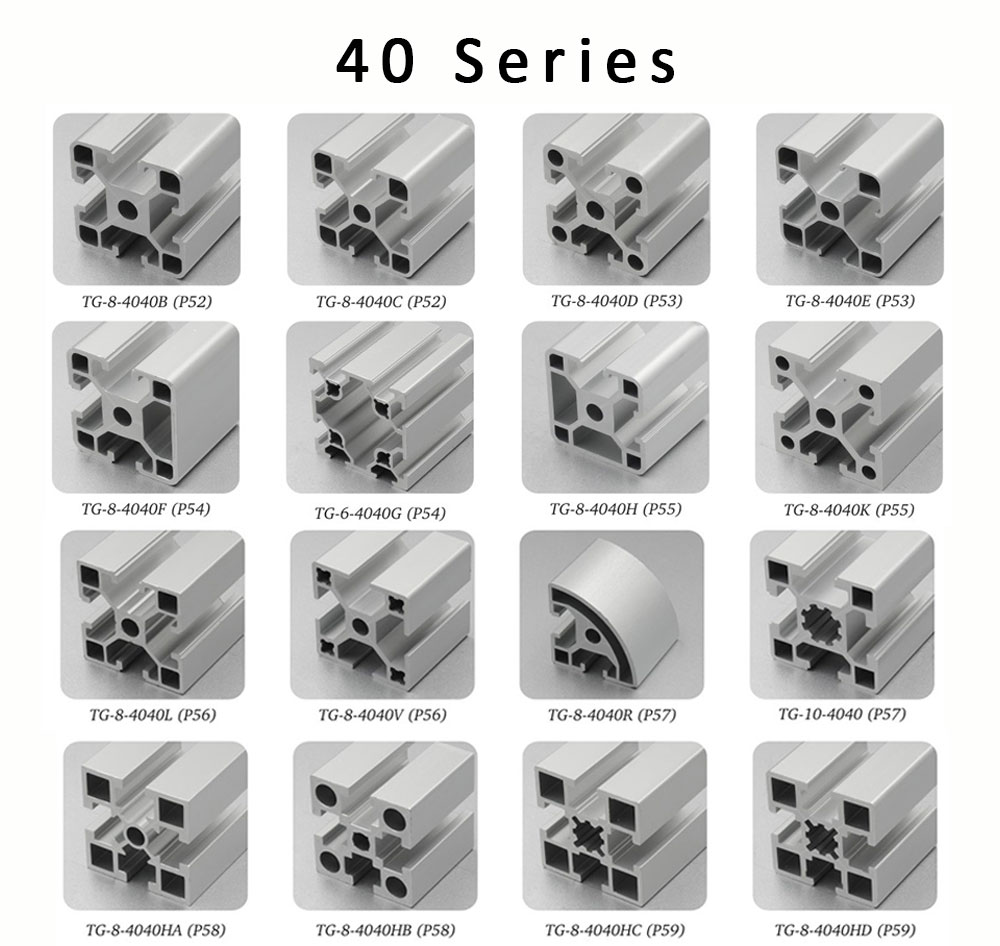

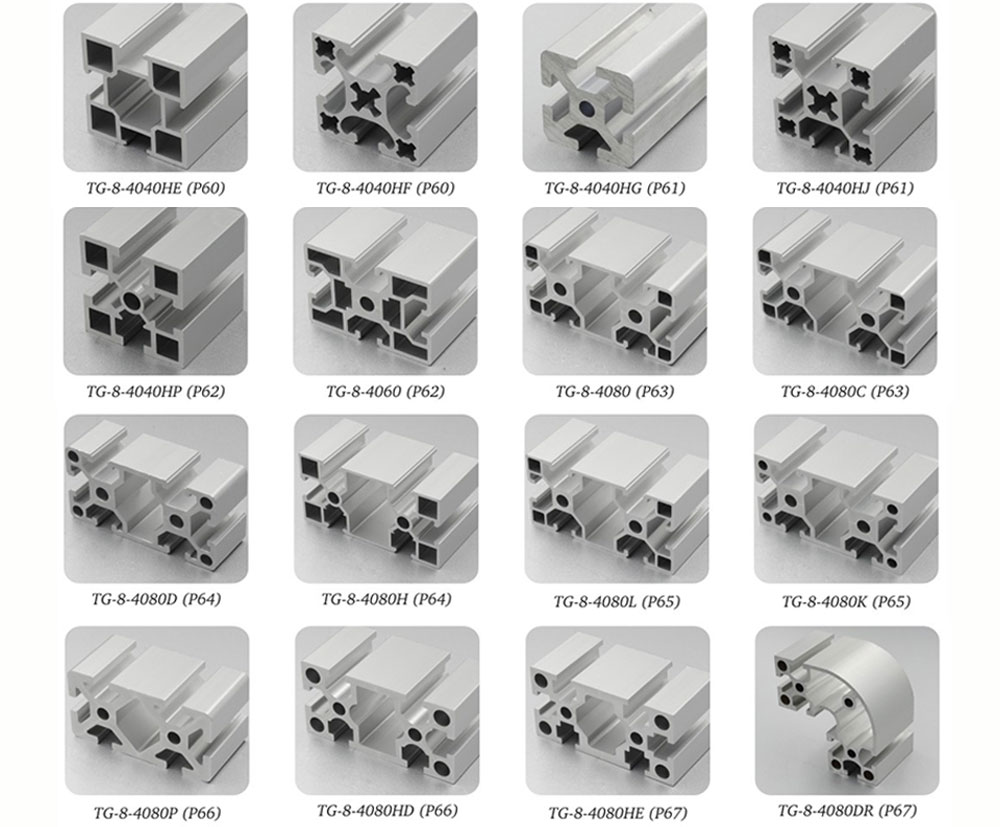

Series 40

This is the most flexible among the T slot series. You can use it with a wide range of hardware accessories like fasteners, mountings, connectors, etc. A key advantage of the series 40 is that it allows use with other T slot series. It is ideal for applications like guards and work benches.

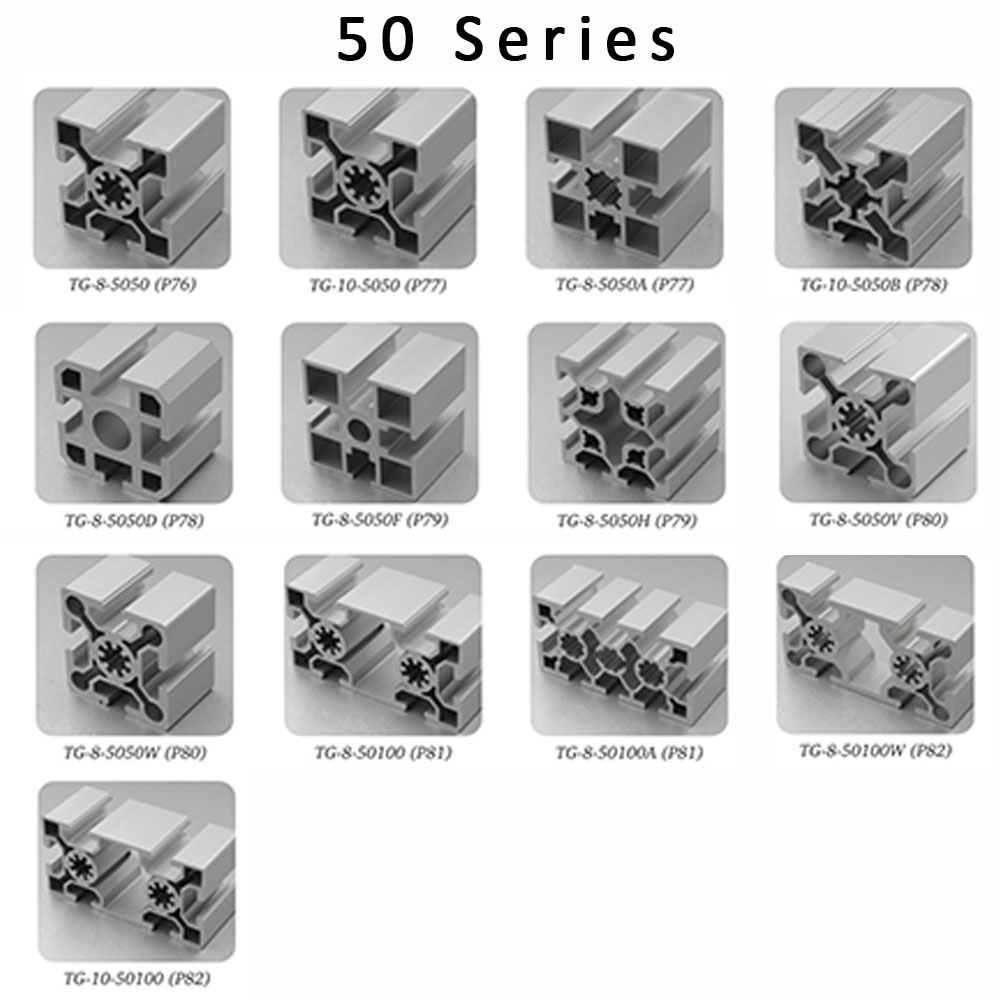

Series 50

Thanks to its easy workability, the series 50 is popular in the machining industry. You can customize different lengths for heavy duty applications.

Advantages of T Slot Aluminum Extrusions

Design Options

T-slots are highly flexible; while engineers are working on different projects, need can arise for adjustments, additions, removal and repositioning. Additionally, the extrusions can easily be assembled and reassembled so you do not need to incur additional cost on design modifications. A quick fix is possible in case you make any structural mistakes. This is an important benefit given the changing customer demands in engineering applications.

Cost Effectiveness

The recyclability and flexibility of t slots deem them a cost, time and labor-saving option. You don't have to dispose of the old workbench or shelves into a landfill. There is little to no waste of material as you can work on a new project to transform these products into structures for new use. This way, the T slots maintain their value over time.

Customization

Sometimes the standard framings won't cut it. T slots allow you to build structures and other products to the specific dimensions, function, and other tailored specifications. This allows for enhanced efficiency and convenience in different working environments.

Strength and Corrosion Resistance

The modular nature of t slots allows for better connecting compared to other weaker aluminum extrusions. You can customize them to any strength requirements like heavy load structures. They are also suitable for building in harsh environments thanks to their corrosion resistance. Additionally, T slots are allowed for cleaner engineering projects as there is minimal waste.

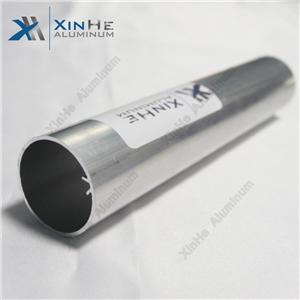

2. V Slots

Definition And Function

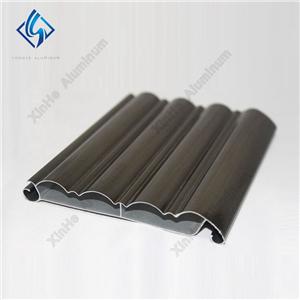

V slots are better solutions for joining different metal parts than the welding technique. There is minimal difference in the structure of V slots and T slots. Infact, they are sometimes used interchangeably.

This however is not recommended as both options are readily available. V slots have a rectangular length but there is a key difference on the groove edges; they are beveled. V slots have more advanced features than T slots which allows for flexibility in design control.

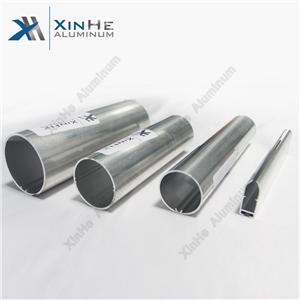

Types of V Slot Aluminum Extrusions

V Slot 2020

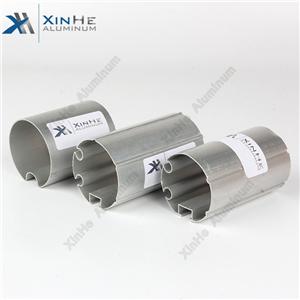

This extrusion is designed in consideration to linear motion applications. They allow for customization and are suitable for applications like camera sliders, CNC machines, printers etc. The 2020 v slots are available in different lengths and can be used with a wide variety of external connectors.

V Slot 2040

This is a rectangular length extrusion popular in building applications thanks to its unique properties like smooth edges. They allow for a wide range of finishing options that enhance their appearance and durability. Other applications are laser and plasma cutters.

V Slot 2060

This is another V slot type suitable for linear motion applications. It is workable and allows for easy mounting on a wide variety of compatible structures. It is made from high-strength aluminum alloys, which makes it high strength and durable. Other applications include router machines and 3D printers.

V Slot 2080

The 2080 extrusion is available in different colors and lengths. You can have it anodized or cut to your required length. It is mostly used in lightweight projects like housings and 3D printers.

Advantages of V Slot Aluminum Extrusions

Flexibility

The characteristics of V slots allow for a wide range of applications. The high tensile strength and durability make it suitable for both lightweight, small DIYs and intricate engineering projects.

Environmentally Friendly

The aluminum material in general is recyclable and its compounds are not harmful to the environment. V slots are durable and can be disassembled after their initial use. This gives the customer value for their money and is a step towards the green initiative.

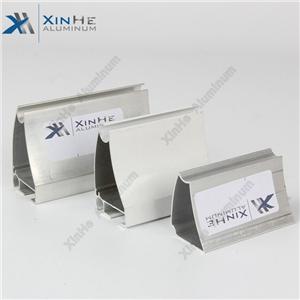

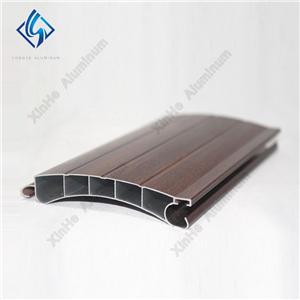

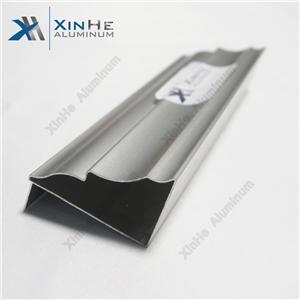

Visual Appeal

V slots are not only used in high efficiency machines and structures, but are also visually appealing. They have smooth edges and a shiny appearance which can be further enhanced using different finishing methods.

High Precision

Precision is key in machining and structural applications. The V slot designs come in various sizes, which allow for precise joints and secure fits. They also allow adjustments in case of any measurement errors.

T Slot vs. V Slot Extrusion Weight Options

● Heavy Duty - This aluminum extrusion weight offers optimum sturdiness. It is tailored for loaded structures and those involving linear motion. It is also used to manufacture heavy machinery. The main advantage of this weight option is the enhanced structural support and efficiency in heavy weight bearing applications. Heavy duty T slot and V slot extrusions are more expensive due to their bulky material.

● Standard - These are T slot and V slot extrusions with a sprinkle of all the strength properties (light and heavy), which make up a blend of average weight profiles. It is the most popular weight option for medium-level intricate applications. Additionally, they cost less than the heavy-duty applications. You can use them for standard workbenches and shelving units.

● Lightweight - This is the cheapest weight option due to its significantly reduced weight. Despite its lightweight properties, it offers durability and efficiency for less demanding applications. Some common products with lightweight T slots and V slots are lightweight framings and machinery.

Key Differences Between T Slot and V Slot Aluminum Extrusions

Edges

One way you can tell apart a T slot from a V slot is by the difference in the edges. The V slot edges are smoother and are beveled, while the T slot ones resemble a T shape.

Another difference in the physical characteristic is that V slots have rails that make linear motions easy in motion control applications.

Finishing Options

T slots are mostly sold untreated. V slots, on the other hand, are available untreated, or you can have them anodized in black.

Aluminum looks good and shiny whether you choose to finish it or not. Finishing options like paint are unsuitable for both V slots and T slots as it easily chips and covers up the authentic look of the aluminum metal.

Connecting Hardware

T slots and V slots are connecting extrusions. However, they need other hardware accessories to serve this function.

Most of this connected hardware is suitable for both extrusions, but they come at varying costs. You can use T nuts or fasteners or go for cheaper options like custom-making 3D connectors.

Cost

V slots offer higher efficiency than T slots. They allow for wheel sliding in framing. For this reason, you will get them at a higher cost than their T slot counterparts. Another contributing factor to the higher cost is that V slots are modern, while T slots are considered traditional.

Applications

There are different types of V slot and T slot extrusions, each with unique applications. Other parameters that affect their uses are weight and dimension. Applications range from DIYs to more complex uses like framings, 3D printers, construction assembly lines, housings, etc. Although both are interchangeable, you can achieve higher efficiency by choosing the one that best suits your application.

Similarities Between T Slot and Slot Aluminum Extrusions

Although the main focus of this write up is on the differences, some similarities between V slots and T slots are:

● Hardware accessories like brackets and T-nuts are applicable on T lots and V slots

● T slots and V slots are not compatible with odd joints

● Using V slots and T slots interchangeably can cause design complications

● Their length cross section is similar

Cross Sectional Design Parameters in Aluminum Extrusion

Complexity

Aluminum profiles are grouped into hollow, solid, and semi hollow. V slots and T slots are classified as multi voids hollow extrusions.

Application Needs

There are standard V slot and T slot sizes. Nevertheless, some applications have special design requirements like high preciseness and cut to size pieces. Some size requirements are too small or too big, hence unavailable in the market of standard extrusions. These extrusions also allow for adjustment of standard extrusions to fit different application demands.

Dimensions

V slots and T slots are predicted to advance even further to allow for more complex dimensions. You can choose a dimension based on the operating conditions and alloy grades. The size of a V slot or T slot does not affect its strength, as small sized extrusions are usable in heavy duty applications.

Angle Radius

The V slot and T slots have multi void edges with different angles. The angles are designed such that stress concentration or wear does not occur during the extrusion process. V slots have angles designed for sliding in linear motion applications.

Thickness

The wall thickness of V slots and T slots is relative to the circumference and shape of the Multivoids. Thicker walls involve a more complex extrusion process.

T Slots and V Slot Customization

The easiest option for less demanding applications is to purchase standard V slots and T slots. Nevertheless, there are various parameters you should consider before you purchase them. The complexity of your application is the key determining factor.

Custom V slot and T slot extrusions offer additional advantages like preciseness, unique design, and improved operation efficiency. You might not get extremely small or large T slot and V slot sizes and lengths at standard extrusion shops.

However, there are reliable aluminum extrusion companies that can tailor them to your application requirements. You can have T slots and V slots custom made from scratch or have the standard dimension options modified to your specifications.

Conclusion

With the information provided, we hope you have an extensive understanding of the properties of T slots and V slots, as well as the key differences. The differences might be minimal but it is important that you factor them in. As mentioned, these extrusions are interchangeable.

However, it is crucial to decide the most suitable one. This will save you the trouble of operation inefficiency, especially in complex structural applications. This knowledge is also handy during your selection process. For high strength standard and custom T slots and V slots, contact XIHUI for a prompt quote.