- Home

- >

- News

- >

- Industrial News

- >

- Why Is LED Heat Sink Made of Extruded Aluminum?

Why Is LED Heat Sink Made of Extruded Aluminum?

Why Is LED Heat Sink Made of Extruded Aluminum?

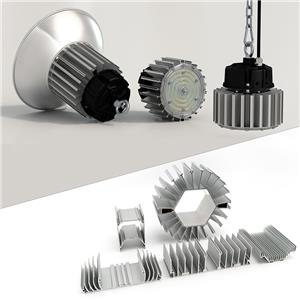

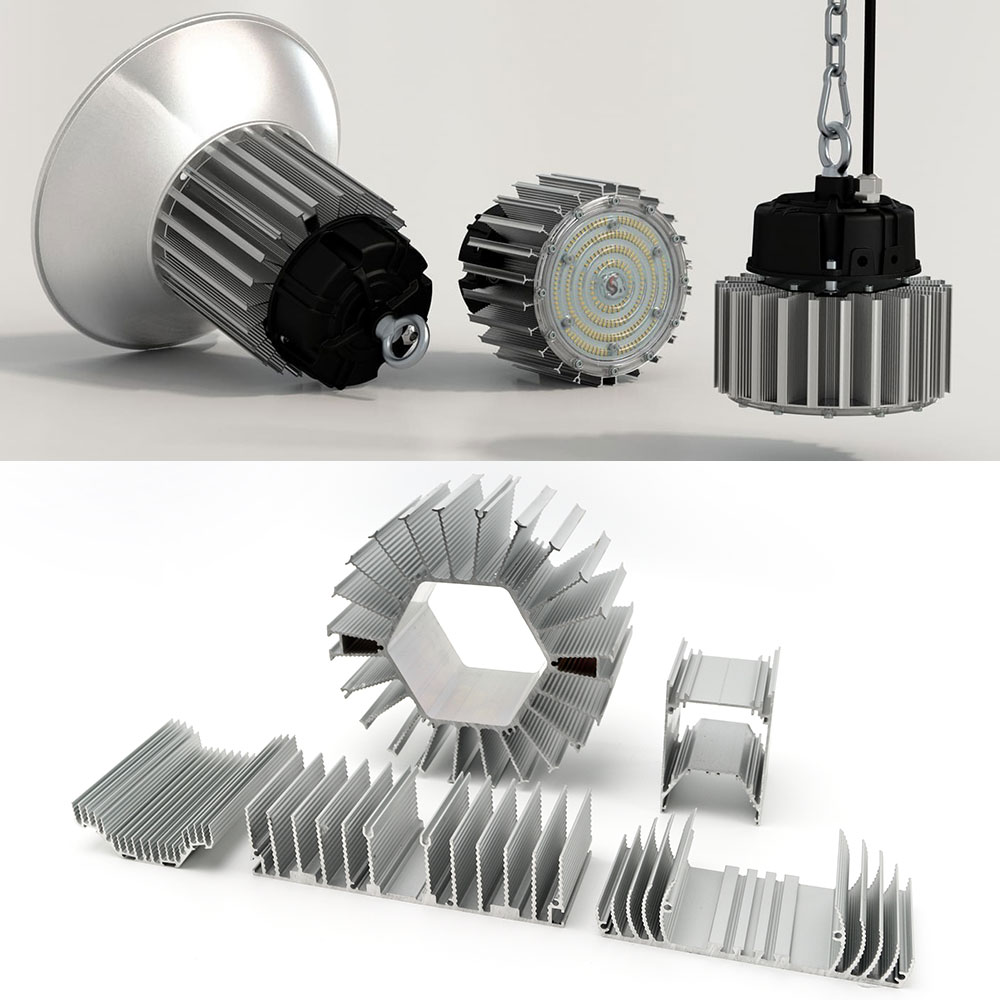

LED heat sink is very important for LED light. Like all electronic parts, LED lighting generates heat energy and temperature rise during use or operation. If the heat dissipation problem is ignored, the LED light will burn out due to high temperature early.

Due to the development of high-power LED technology, LED lights to face severe challenges in thermal management and heat dissipation design, because the increase in temperature will not only cause the brightness to decrease, but also accelerate the degradation of the lamp body and packaging materials when the temperature exceeds 100 degrees Celsius. Therefore, in addition to the heat dissipation technology of the LED packaging component itself, the LED heat sink is the biggest key to maintaining the life of the light.

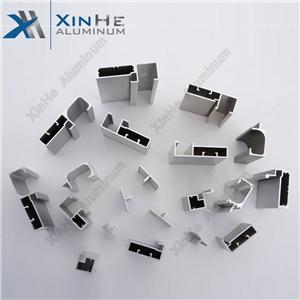

Then the selection of the LED heat sink is very critical. The conventional LED heat sink materials on the market are plastic and aluminum alloy.

PLASTIC

It is well known that the heat resistance of LED lights is very poor, which will inevitably bring about the problem of the life of the wick. However, the plastic materials are very passive in heat dissipation, and are mostly air-cooled or even closed. Like some lamps, a plastic sleeve is added between the driver board and the aluminum LED heat sink to increase the reliability of the insulation, and heat dissipation silicone is also required to improve the heat dissipation capability. Generally, the internal temperature of this type of lamp will be 70 or 80 degrees. And if both heat dissipation and weight are issues, it is difficult to ensure heat dissipation. It is a difficult choice in this existing design, and there is no feasible standard. And the price of plastic will be expensive, so plastic is not suitable for LED lights.

ALUMINUM

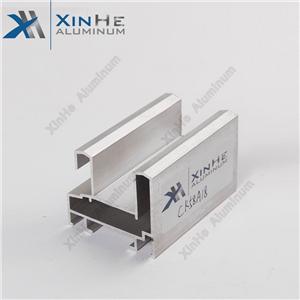

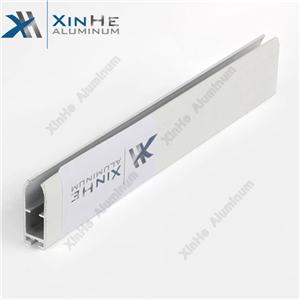

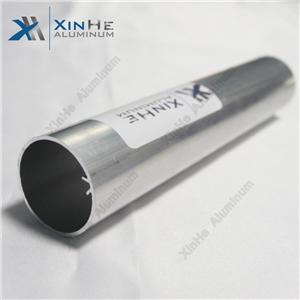

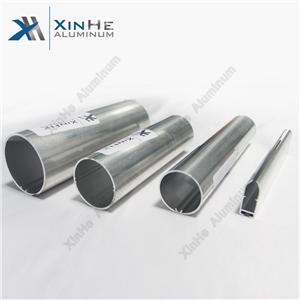

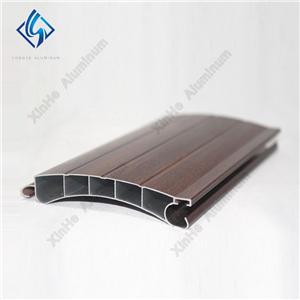

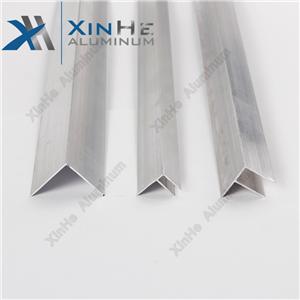

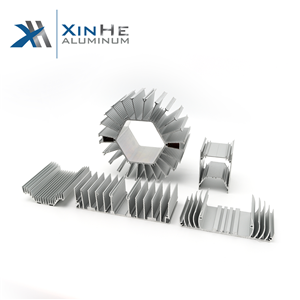

Aluminum alloy is recognized as a good heat dissipation material in the production of LED lights and has a good heat dissipation coefficient. Aluminum alloy has good thermal conductivity, which can help LED lamps to dissipate heat well. And the aluminum LED heat sink has the characteristics of lightweight, which is convenient for installation and handling. When the heat dissipation capacity is the same, its weight is only one-eleventh of the cast iron heat sink, one-sixth of the steel heat sink, and one-third of the copper heat sink.

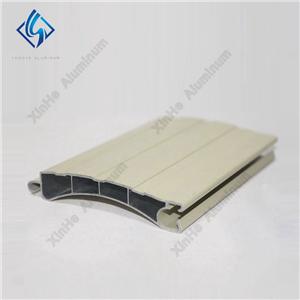

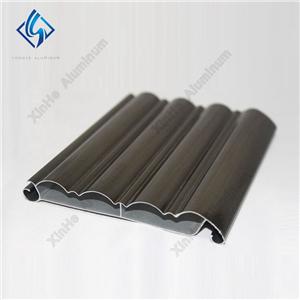

The aluminum heat sink has the characteristics of beautiful appearance, lightweight, good heat dissipation performance, and good energy-saving effect. The decorative performance of aluminum profiles is very strong: when aluminum materials are used in decoration or certain specific occasions, they need to be anodized and painted on the surface to obtain the corresponding color and surface structure. Aluminum LED heat sink has good corrosion resistance. Its anode treatment performance, surface treatment performance, coating performance are very good.

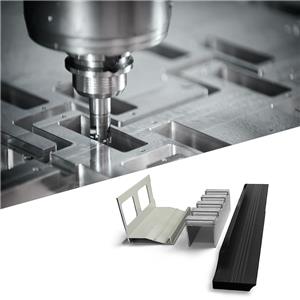

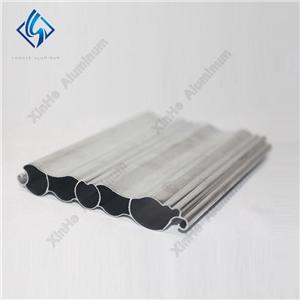

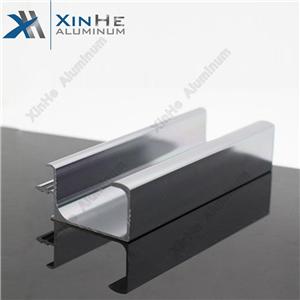

From the aspect of making a heat sink, aluminum alloy is the best choice for making a LED heat sink. Whether it is energy-saving, material saving, decoration, price, weight, etc., all have advantages. The aluminum LED heat sink is also becoming more and more popular with extruded aluminum profiles because the extruded blanks have good size consistency, short production cycles, and relatively low costs.