Shaping aluminum pipes is a vital task for industries like building and production, where accuracy and strength matter. At Foshan XiHui Aluminium Co., Ltd., we focus on supplying top-notch aluminum pipes designed for various projects. But is bending an aluminum pipe as simple as it seems? In this blog, we look at the main factors that affect how easily aluminum pipes can be shaped, the methods used, possible problems, and how our skills ensure great results for your needs.

Properties of Aluminum Pipes Relevant to Bending

The ability to shape aluminum pipes depends on several material traits that decide how well they can be formed without losing strength. Knowing these traits is key to making accurate bends.

Material Composition and Its Influence on Flexibility

Aluminum is light yet sturdy, making it a favored choice for pipes. Its flexibility comes from its makeup, especially the addition of elements like magnesium, silicon, or copper. Pure aluminum is very bendable but not very strong. Alloys, however, boost durability, which can change how easy it is to bend.

Variations in Aluminum Alloys and Their Bendability

Different aluminum alloys show different levels of bendability:

- 3000 Series: These are great at resisting rust and have medium strength. They are fairly easy to bend, perfect for projects needing flexibility.

- 5000 Series: These provide more strength and rust resistance. But they might need extra force or heat to bend because they are stiffer.

- 6000 Series: These balance strength and formability, often used in building. They bend well with the right methods, but care is needed to avoid cracks.

Picking the right alloy is important. For instance, our versatile aluminum round tubes are made from high-quality alloys to ensure easy bending for building and industrial uses.

Strength and Ductility as Key Factors

Ductility means the ability to change shape without breaking. It’s a major factor in bending. Aluminum’s ductility depends on its alloy and temper. Softer tempers, like O-temper, are more ductile and simpler to bend. Harder tempers, like T6, are stronger but less flexible. Balancing strength and ductility keeps the pipe’s shape after bending.

Temperature’s Impact on Aluminum Ductility

Temperature greatly affects how ductile aluminum is. At room temperature, aluminum is bendable. Heating it to 300 [300–400°F (150–200°C)] makes it more pliable, so bending becomes easier. But overheating can weaken the material. Controlled heating, as explained in our heat-assisted bending guide, ensures safe and effective results.

The Importance of Proper Support During Bending

Without good support, aluminum pipes might buckle or deform. Using tools like mandrels or internal supports during bending keeps the pipe’s shape, especially for thin or small pipes. Our advanced technology ensures steady support for reliable results.

Techniques for Shaping Aluminum Pipes

Getting clean, precise bends needs the right methods and tools. Here’s a look at the ways we achieve high-quality bent aluminum pipes.

Common Methods for Achieving Precise Bends

Manual vs. Machine-Assisted Bending

- Manual Bending: This works for small projects or softer alloys. It uses tools like pipe benders. It’s affordable but less accurate and takes more effort.

- Machine-Assisted Bending: Machines offer great accuracy, ideal for complex shapes or large batches. At XiHui Aluminium, we use modern machines to ensure precision and consistency.

Heat-Assisted Bending Methods

Heating aluminum pipes reduces the effort needed for bending. It also lowers the chance of cracks. Methods include:

- Torch Heating: This heats small areas. It needs careful temperature control.

- Oven Heating: This heats larger pipes evenly, ensuring steady flexibility.

We suggest using tools like infrared thermometers to check temperatures and avoid damage.

Tools and Equipment Used in the Bending Process

| Tool/Equipment | Purpose | Best For |

| Pipe Bender | Manual bending | Small projects, softer alloys |

| Bending Machine | Precise, automated bending | Complex shapes, large batches |

| Mandrel | Internal support | Thin or small pipes |

| Heat Gun/Torch | Heat application | Heat-assisted bending |

Our top-notch equipment ensures every bend meets your needs, whether for custom aluminum U-channels or round pipes.

Challenges in Shaping Aluminum Pipes

Shaping aluminum pipes can be tricky. Knowing these issues helps avoid problems and get perfect results.

Risks of Cracking or Wrinkling During the Process

Cracking happens when the pipe is pushed too hard, especially with harder alloys or wrong methods. Wrinkling often occurs in thin pipes if there’s not enough support inside. Using mandrels and slow bending speeds reduces these risks.

Thickness and Diameter Considerations

Thicker pipes need more force to bend, which raises the chance of cracking. Thinner pipes are likely to wrinkle. Smaller pipes are harder to bend without deforming. Our skills ensure the best approach for any pipe size.

The Role of Surface Finish in Maintaining Pipe Strength

A smooth surface lowers friction during bending. This prevents scratches or weak spots. We apply protective coatings or polish the pipes to keep them strong, especially for decorative uses like slim glass door frames.

Uses for Bent Aluminum Pipes

Bent aluminum pipes are useful in many fields, such as:

- Building: Frameworks, railings, and supports.

- Cars: Exhaust systems and chassis parts.

- Furniture: Curved designs for modern looks.

- Aerospace: Light, strong pipes for planes.

Our aluminum pipes are built to meet the needs of these varied uses, ensuring strength and accuracy.

XiHui Aluminium: Your Trusted Aluminum Pipe Supplier

At Foshan XiHui Aluminium Co., Ltd., we take pride in offering high-quality aluminum pipes, backed by 30 years of experience. Here’s why we’re your go-to partner:

Using Advanced Technology

Our modern machines ensure accurate bending, cutting, and finishing. They meet the tightest standards for your projects.

Commitment to Top-Quality Materials and Standards

We use the best aluminum alloys. Our quality control team checks every order before it ships.

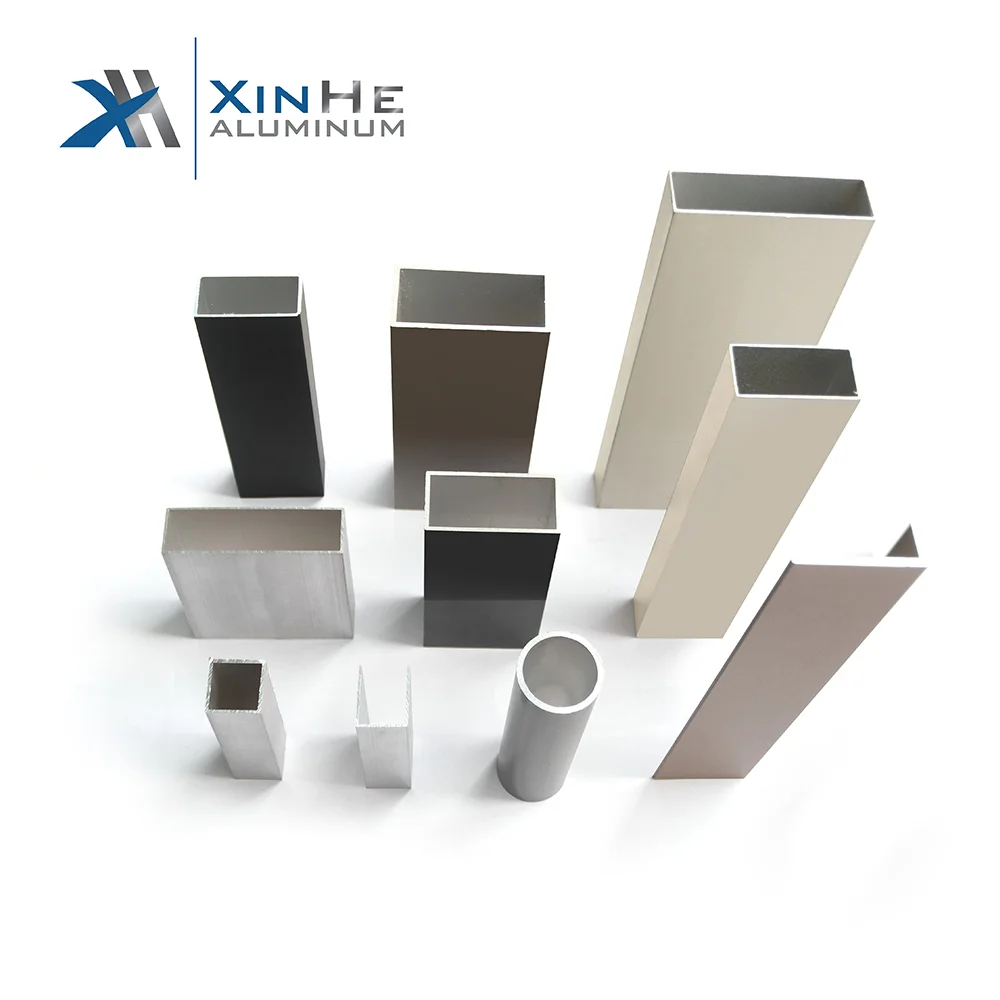

Wide Range of Aluminum Pipes for Different Uses

From round pipes to custom shapes, our product range serves industrial, building, and decorative needs.

Skills in Meeting Custom Needs

Need a specific alloy, size, or bend? We provide tailored solutions to fit your exact needs, ensuring smooth use in your projects.

FAQs About Shaping Aluminum Pipes

Q1. What is the best aluminum alloy for shaping purposes?

A1. The 3000 series, especially 3003, is often the best for shaping. It’s very flexible and resists rust. For projects needing more strength, 6061 from the 6000 series works well, but it needs proper heat and support.

Q2. Can aluminum pipes be shaped without heat?

A2. Yes, softer alloys like 3003 can be shaped without heat. You can use manual or machine methods. But harder alloys or tight bends may need heat to improve flexibility and avoid cracks.

Q3. How can I prevent wrinkles during the shaping process?

A3. To avoid wrinkles, use a mandrel for internal support. Apply lubrication to reduce friction. Control bending speed carefully. Choosing a thicker pipe or a softer alloy can also help prevent wrinkling.